54

HARDI

®

N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

*Standard mesh

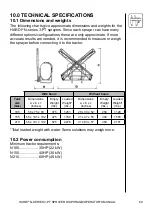

6.3 Nozzles And Fittings

Poor seals are usually caused by:

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign materials

Therefore, in case of leaks; DO NOT overtighten. Disassemble, check

condition and position of O-ring or gasket, clean, lubricate and reas-

semble. For radial type seals (O-ring) hand tighten only, do not use

pliers (Fig. 27).

The O-rings need to be lubricated ALL THE WAY AROUND before fi t-

ting on to the nozzle tube.

HARDI

®

recommends using a vegetable based oil to prolong the life of

the O-ring.

ISO Nozzle

Size

Suction Filter Self Cleaning

Filter (optional)

Nozzle

Screen

Inline Filters

(optional)

Pink (075)

Orange (01)

Green (015)

Yellow (02)

50

100

100

100

Lilac (025)

Blue (03)

50

80

80

80

Red (04)

& Larger

30*

50*

50*

50*

Fig. 27