26

HARDI

®

FOAM MARKER STANDARD VERSION

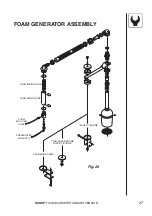

10.0 FOAM GENERATOR ASSEMBLY

Note - For maximum performance the clear hose should be as long

as practically possible.

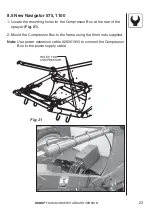

1. Locate the Foam Generator on the

front side of the outer wing of the

spray boom.

2. Mount the Foam Generator vertically,

with the

3

/

4

” 90° hose barb at the top.

The retaining clip and mounting fl at

bar is placed to fi t around the base of

the foam mixing chamber. The fl at bar

is clamped to the boom structure with

the hose clamps provided (

Fig. 24

).

3. For cleaning of the Foam mixing mesh

and the check valve, the Foam Gener-

ator must be dis as sem bled from the bottom. Flush the fi tting and mesh

with clean water to remove any built up residue. For optimum foam do

not roll up the foam mixing mesh, bunch up the mesh inside the tube

from end to end.

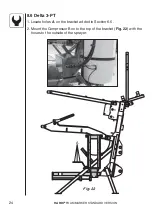

10.1 Eagle™ Booms

- Mount the Foam Dropper mount

bracket as close to the outer nozzle as

possible as shown in (

Fig. 25

).

- Adjust the breakaway tension by tight-

ening or loosening the pivot bolt.

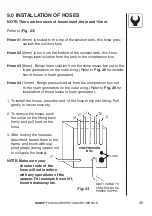

- Connect the clear reinforced hose

to the

3

/

4

” hose barb on the dropper

assembly and to the

3

/

4

” hose barb on

the foam generator assembly.

- Secure hose with cable ties as nec-

essary.

- Connect the polyethylene 8mm

and 10mm hoses to the fi ttings

at the base of the Foam Generator.

Fig. 25

Fig. 24