17

Fault

Probable cause

Control / remedy

Check suction tube and fittings.

Check tightness of pump diaphragm

and valve covers.

Fill suction hose with water for initial

prime.

Clean filters.

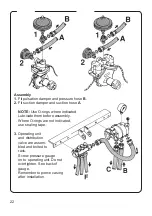

Recheck assembly.

Check for obstructions and wear.

Check for dirt at inlet of gauge.

Clean all filters. Fill with cleaner

water.

Check flow rate and replace nozzles

if it exceeds 10%.

Check vent is clear.

Clean all filters.

Check tightness / gaskets / O-rings

of all fittings on suction side.

Use foam damping additive.

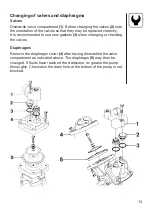

Replace. See section Changing

valves and diaphragms.

No spray from

blower when

turned on.

Lack of

pressure.

Pressure

dropping.

Pressure

increasing.

Formation of

foam.

Liquid leaks

from bottom of

pump.

Air leak on suction.

Air in system.

Suction / nozzle

filters clogged.

Incorrect assembly.

Pump valves blocked

or worn.

Defect pressure gauge.

Filters clogging.

Nozzles worn.

Tank is airtight.

Nozzle filters begin-

ning to clog.

Air is being sucked

into system.

Excessive liquid

agitation.

Damaged diaphragm.

Summary of Contents for BL Series

Page 11: ...11 1 X 40 2 X 20 3 X 40 4 X 40 11 6 10 10 8m SB T213 0010 T201 0002 ...

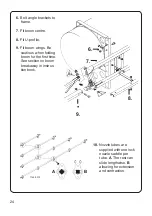

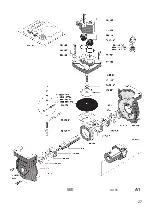

Page 27: ...27 500 4 9 95 A1 ...

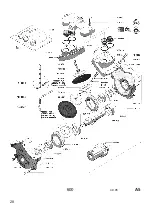

Page 28: ...28 600 4 9 95 A5 ...

Page 29: ...29 B5 15 5 79 ...

Page 30: ...30 B6 18 2 91 ...

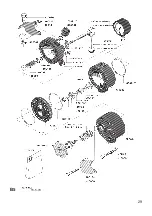

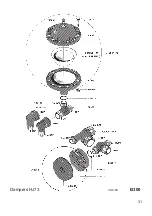

Page 31: ...31 Dampers HJ73 30 9 93 B300 ...

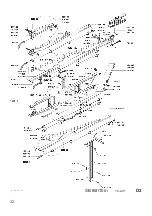

Page 32: ...32 SB 6 8 10m 18 2 91 D2 ...

Page 33: ...33 ...

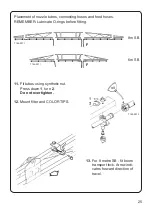

Page 34: ...34 BL 200 300 18 2 91 E2 ...

Page 35: ...35 Notes ...

Page 36: ...36 Notes ...