Page 9

For technical questions, please call 1-888-866-5797.

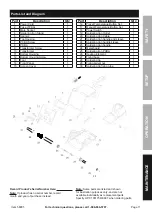

Item 58005

SA

FE

TY

OP

ERA

TI

O

N

MAINT

ENANC

E

SE

TUP

Settings

To enter Settings mode, press and

hold for three seconds.

1.

Calibration

a. Press 1, Screen will display

CAL

and

last calibration value will be shown.

b. Calibrate with Soldering Iron Tip

Thermometer (sold separately).

• Clean and tin Tip, then measure

temperature and record.

• Compare actual temperature to displayed

temperature. Record any difference.

• Adjust difference by pressing .

Example: measured temperature is 380° F,

displayed temperature is 400° F, difference

is -20° F. Press down to -20°.

c. Press 1 when finished to store setting.

2.

Temperature Increments

a. Press 2, Screen will display

F I

Π

and current setting will be shown.

Press

to change setting.

•

O

Π

- Temperature will adjust 1° for

each press of Manual Buttons.

•

OFF

- Temperature will adjust 5° for

each press of Manual Buttons.

b. Press 2 when finished to store setting.

3.

Switch Temperature Scale

a. Press 3, Screen will display

C - F

and current scale will be shown.

b. Press

to change temperature scale.

c. Press 3 when finished to store setting.

4.

Automatic Standby

a. Enter Settings mode, then press .

b. Press 1, Screen will display

Stb

and

current status will be shown.

c. Press

to set Standby time

(1 to 120 minutes) or set to

OFF.

d. Press 1 when finished to store setting.

5.

Automatic Shutdown

NOTE:

This feature will only work if Automatic

Standby is on. After entering Shutdown,

the Soldering Station cannot be controlled

until power is turned off and back on.

a. Enter Settings mode, then press .

b. Press 2, Screen will display

Sd

Π

and

current status will be shown.

c. Press

to set Shutdown time

(1 to 120 minutes) or set to

OFF.

d. Press 2 when finished to store setting.

6.

Sound

a. Enter Settings mode, then press .

b. Press 3, Screen will display

bL

and

current status will be shown.

c. Press

to set to

ON

for audible beep

when pushing Buttons or set to

OFF

.

d. Press 3 when finished to store setting.

7.

Restore Factory Settings

a. Enter Settings mode, then press twice.

b. Press 1, Screen will display

FAC.

c. Press

to set to

ON

then

press 1 to restore settings

.

8.

Manually Exit Settings

Note:

After 10 seconds of no activity,

unit will automatically exit Settings.

a. While in Settings mode, press until

bottom of Screen displays

FAC

and

ESC

.

b. Press 2, Screen will display

ESC.

c. Set to

ON

then press 2 to exit settings

.