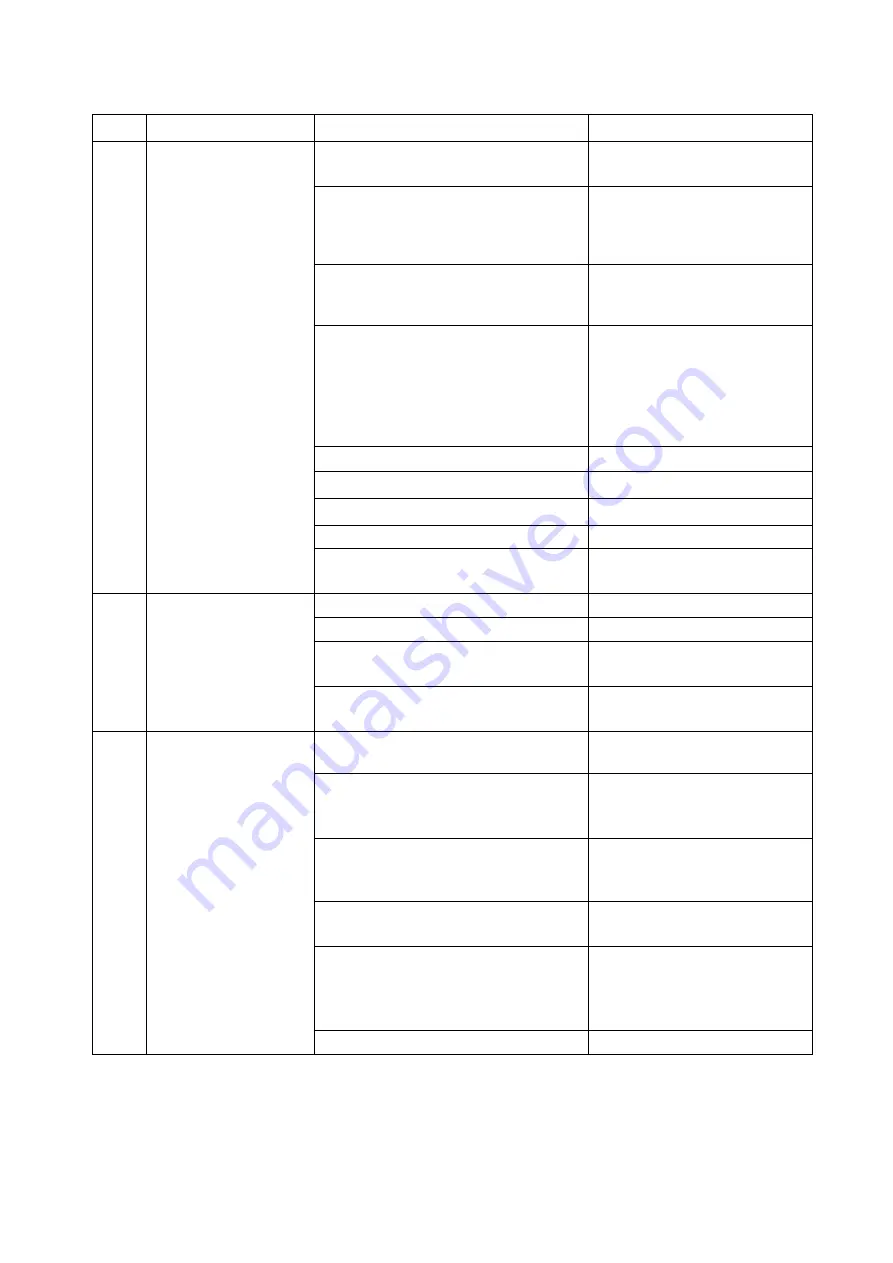

17

NO.

Failure

Causing

Solution

7

Setting cutting

thickness cannot be

achieved

1

、

Input voltage cannot get to

rated voltage

Inputting voltage

2

、

Input power supply capacity is

toosmall and cutting line

preesure is too big

Increase input power supply

capacity

3

、

Input compressure air pressure

is too low or too high

Adjusting the air pressure

4

、

Input air flow is too small,such

as preesure meter drops to

0.3Mpa during the

operation ,and pressure recover

after stop working

Increase the compressed air

flow to 300L/min

;

If the air

hose is small ,please change

the hosediameter to more

thanΦ8mm

5

、

Cutting speed is too fast

Reduce cutting speed

6

、

Nozzle burned

Change

7

、

Electrode has burned

Change

8

、

Nozzle size is not fitted

Change to the right size

9

、

Air hose or cutting cable

damaged

Repair or change

8

Kerf with wide

incision and poor

quality

1

、

Cutting speed is too slow

Adjusting speed

2

、

Nozzle and electrode burned

Change

3

、

material

、

thickness and option

of thickness have wrong position Adjusting

4

、

Nozzle type is wrong and

diameter is too big

Change a right size one

9

Torch burned

1

、

Nozzle or electrode loosing

Fasten the nozzle or

electrode

2

、

Torch wire connector

loosing ,or cable /hose

damaged

Check on time

3

、

Torch connrctor with poor

insulation condition

Make sure the torch

connector with good

insulation

4

、

Shield cap of cutting torch has

been damaged

Change on time

5

、

Compressed air is over wet

Clear the water in “air

pressurevalve”,if the air wae

over wet ,please install

water flilter Lv1~2

6

、

Electrode burned

Change a new one