16

6.0 AMP ANGLE GRINDER

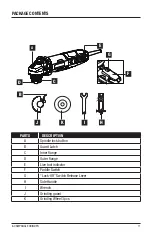

CARE AND MAINTENANCE

WARNING:

• Always disconnect the device before performing any adjustment or maintenance

operation.

if the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

• Disconnect from the power supply immediately if the supply cord is damaged.

Take care not to expose this tool to the rain.

• If the carbon brushes need to be replaced, have this done by a qualified repair

person (always replace the two brushes at the same time)

1. Cleaning

• Avoid using solvents when cleaning plastic parts. Most plastic parts are susceptible to

damage from various types of commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust, etc.

2. Lubrication

• All the bearings in this tool are lubricated with a sufficient amount of high grade lubricant

for the life of the unit under normal operating conditions, therefore no further lubrication

is required.

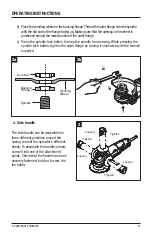

3. Tightening the disc safety guard

Disconnect the plug from the electrical outlet.

a) Remove the flanges and the wheel; refer to the section

“Grinding Wheel

Assembly”

.

b) Open the guard latch and rotate the guard to a proper position.

c) Close the guard latch and tighten the screw on the guard with the wrench supplied.

NOTE:

After the wheel guard is tightened, the guard should be fixed firmly when the latch is

closed and rotated normally when the latch is opened.

Summary of Contents for HAAG060

Page 20: ......