22

2000225116B

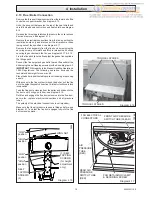

8.4 Service Checks

Inspect the ignition and sensing electrodes and clean and

replace as necessary, see diagram 8.12.

Check the condition of the side and rear insulation panels in the

combustion chamber.

Check the condition of the seals on the boiler access door and

the combustion chamber cover.

Examine the flue hood and terminal to make sure they are clean

and clear of obstructions.

Refit all parts.

Light the boiler and carry out functional tests as described in

section 6.

BURNER

GRAPHITE

COATED NUT(2)

SUPPLY

FEED PIPE

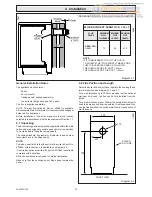

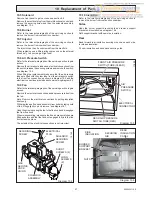

8.2 Boiler Flueways

Remove flueway baffles noting that there are 3 centre and 2

side flueway baffles, see diagram 8.8.

Place a sheet of paper in the combustion chamber to catch any

flue debris.

Thoroughly clean boiler flueways and fins with a suitable stiff

brush.

Replace in reverse order, after completing the relevant

instructions in sections 8.3 and 8.4.

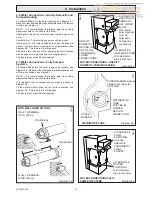

8.3 Burners and Injectors

Remove the screws and nuts securing the burner support

bracket to the combustion chamber cover, see diagram 8.9.

Remove the graphite coated nuts on the supply feed pipe at the

rear of the burner to release the burner, see diagram 8.10.

Clean the burner. Use a vacuum cleaner or suitable stiff brush

(not wire) to clean the burner thoroughly, making sure that all

the burner ports are clear and unobstructed.

Check the burner injector for blockage or damage and replace

if necessary, see diagram 8.11.

With the burner removed the injector can be inspected and

cleaned as necessary.

For cleaning do not use a wire or sharp instrument on the hole.

If removed, use a little suitable sealant on the external thread

when refitting to make sure a gas tight seal is made.

Diagram 8.8

FLUEWAY

BAFFLE

HEAT

EXCHANGER

8 Servicing

Diagram 8.10

Diagram 8.9

BURNER SUPPORT

BRACKETS

SCREWS &

NUTS (2)

SIDE

FLUEWAY

BAFFLE

HEAT

EXCHANGER

IGNITION

ELCTRODE

(Black cable)

SENSING

ELECTRODE

(White cable)