PAGE 4

98593C (Rev. C - 01/15)

WCFS*G*L*R WC8AFSQ*1G WC8AFSQ*2GJO

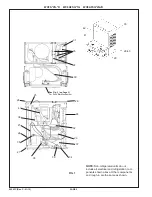

HANGER BRACKETS & TRAP INSTALLATION

1

) Remove hanger bracket fastened to back of cooler by

removing one (1) screw.

2) Mount the hanger bracket and trap as shown in Figure 2.

NOTE:

Hanger Bracket MUST be supported securely. Add fix-

ture support carrier if wall will not provide adequate support.

IMPORTANT:

•

5-1/2 in. (140mm) dimension from centerline of unit to

centerline of trap must be maintained for proper fit.

Anchor hanger securely to wall using all mounting holes.

3) Install straight valve for 3/8" O.D. unplated copper tube.

INSTALLATION OF COOLER

4) Hang the cooler on the hanger bracket. Be certain the

hanger bracket is engaged properly in the slots on the

cooler back as shown in Figure 2.

5) Loosen the two (2) screws holding the lower front panel at

the bottom of cooler base and two (2) screws at the top.

Remove the front panel and set aside.

6) Connect water inlet line--See Note 4 of General Instructions.

7) Remove the slip nut and gasket from the trap and install

them on the cooler waste line making sure that the end of

the waste line fits into the trap. Assemble the slip nut and

gasket to the trap and tighten securely.

START UP

Also See General Instructions

8) Stream height is factory set at 35 PSI. If supply

pressure varies greatly from this, adjust screw, ac-

cessible by removing front panel (Item 7, Fig. 3). CW

adjustment will raise stream and CCW adjustment will

lower stream. For best adjustment, stream should hit

basin approximately 6-1/2” (165mm) from bubbler.

9) Replace the front panel and secure by retightening

four (4) screws.

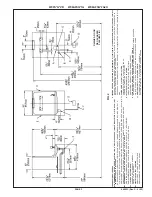

PUSH BAR MECHANISM

LEGEND

A) Note: Water flow direction

B) Adjust this screw to eliminate mechanism “Free Play” or continuous

flow from bubbler conditions. (See ADJUSTMENT PROCEDURE)

C) Stream height adjustment (see note #8)

Water Valve Mechanism - ADJUSTMENT PROCEDURE:

- Turn adjustment screw (Item 9) “Counter-Clockwise” until water flow from bubbler starts.

- Turn adjustment screw “Clockwise” until water flow stops, THEN turn an additional 1/2 turn.

NOTE:

Adjustments stated above are viewed from underneath unit (bottom side of dispenser

panel Item 1)

NOTE:

If continuous flow occurs at the end of the compressor cycle, turn cold control (Item

46) counterclockwise 1/4 turn.

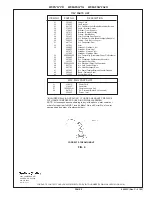

ITEM NO.

PART NO.

Panel - Bottom Dispenser

Kit - Push Bar/Pivot Blocks/Bumpers/Rivets

Kit - Pushbars (Front & Sides)/Inserts/Nuts

Kit - Front/Side Pushbar Bracket/Screws

Panel - Right Side

Panel - Left Side

Panel - Front Push

Screw - Regulator Brkt. Mtg.

Screw - Shoulder x 1/2" Lg.

Kit - Regulator/Holder/Nut

Bracket - Regulator Mounting

Hex Nut

26588C

98537C

98895C

98789C

See Color Table

See Color Table

See Color Table

75502C

70935C

98531C

23003C

40045C

Item No. 5

Part No.

(w/o hole)

COLOR TABLE

Platinum Vinyl

Stainless Steel

Almond Vinyl

Slate Vinyl

26644C

26637C

26636C

26646C

26659C

26652C

26651C

26661C

26614C

26607C

26606C

26616C

PANEL COLOR

1

2

3

4

5

6

7

8

9

10

11

12

DESCRIPTION

26629C

26622C

26621C

26631C

26599C

26600C

26601C

26602C

Item No. 5

Part No.

(with hole)

Item No. 6

Part No.

(w/o hole)

Item No. 6

Part No.

(with hole)

Item No. 7

Part No.

FIG. 3

6

4

3

4

7

3

3

3

3

4

2

8

9 B

2

C

4

4

2

12

11

10

10

10

1

3

4

5

A