8

Control

Control

IM Series controllers and meters can be operated using digital or analog communication.

Digital communication can be performed using Alicat FlowVision™ 2.0 software, ASCII

serial commands, Modbus-RTU, or analog signals.

•

•

•

Modbus RTU:

•

Analog Signals:

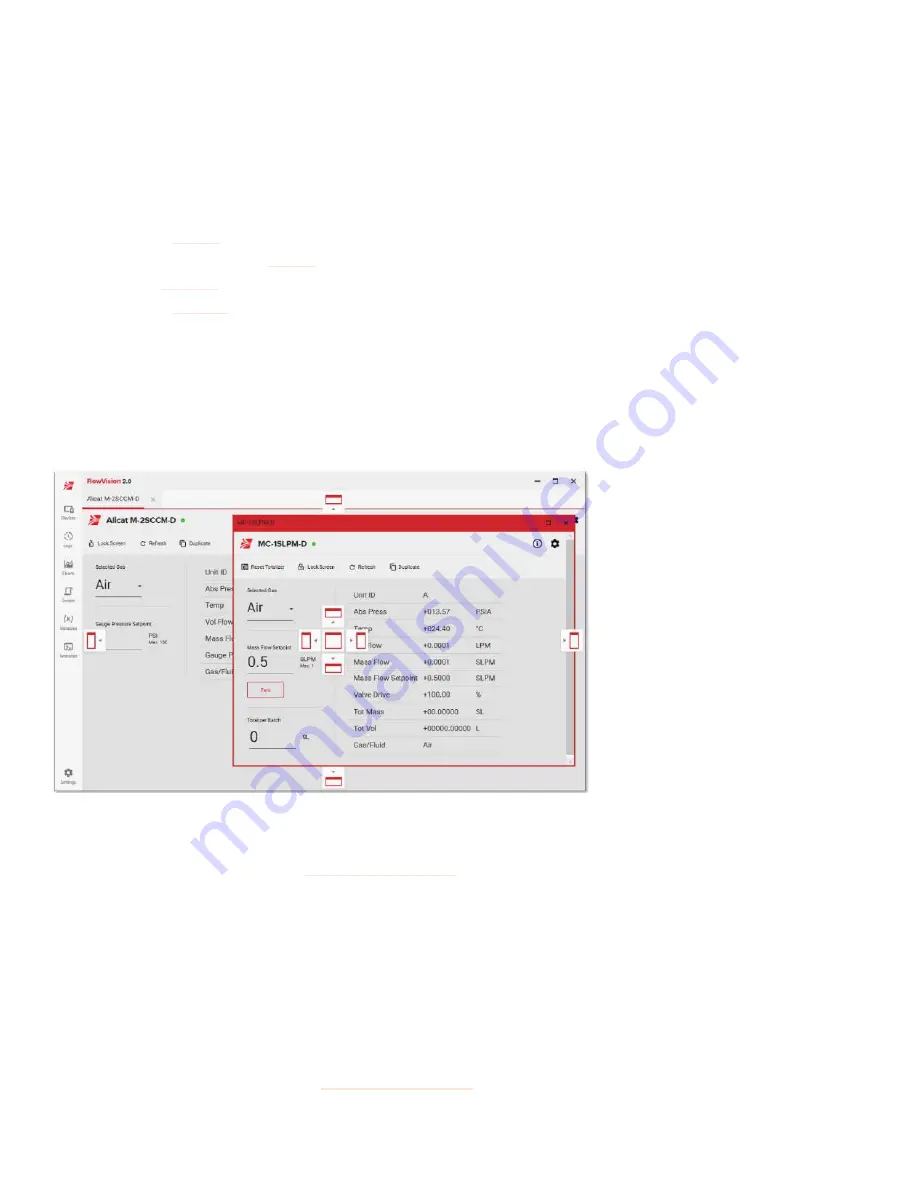

FlowVision 2.0

FlowVision™ 2.0 is Windows-based software that enables easy collection and analysis

of data from Alicat controllers and meters. FlowVision controls the device, runs scripts,

and logs and charts data. It also provides easy access to select the gas, amount of

flow averaging, and PID loop tuning to adjust response speed and stability for some

applications.

Establishing Communication

To connect your device to FlowVision 2.0:

1.

Download FlowVision 2.0 from

and install.

2.

With the device turned on and connected to the computer, start FlowVision 2.0.

3.

Click Devices in the top left corner.

4.

Click the green plus sign to add your controller/meter.

5.

Select Wired for the connection type.

6.

Specify the connection settings. By default, the Device ID is A, and the Baud Rate

is 19200. The Port is dependent on which COM port the device is connected to.

7.

Specify a Name if desired. FlowVision 2.0 generates a name if the field is blank.

8.

Click Add to complete the process.

Please see the FlowVision 2.0 manual at

alicat.com/flowvision

for detailed instructions

on operating your device through FlowVision.