Page

51

SmartFOAM

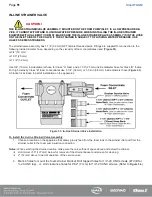

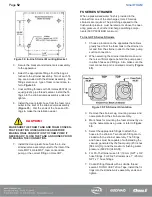

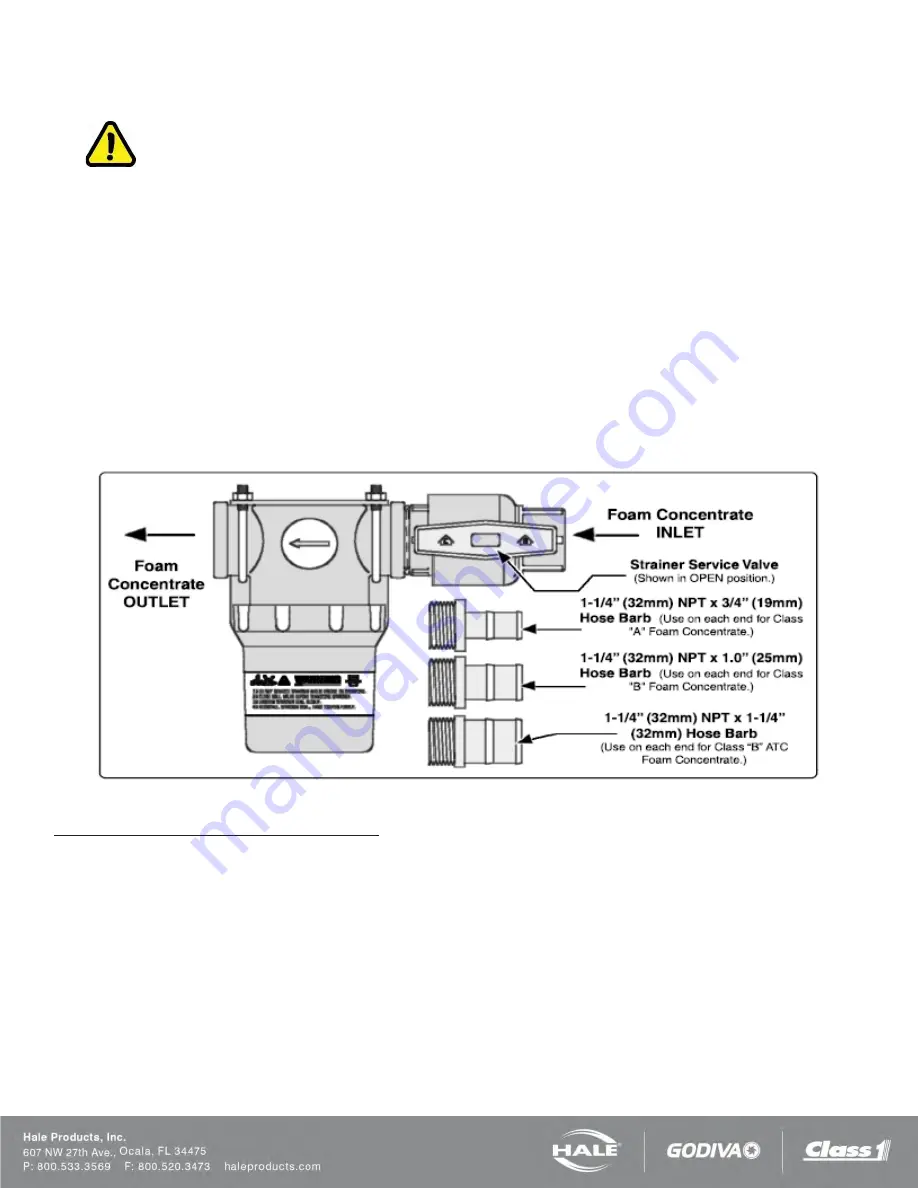

IN-LINE STRAINER VALVE

CAUTION!

THE IN-LINE STRAINER/VALVE ASSEMBLY, MOUNTED ON THE FOAM PUMP INLET, IS A LOW PRESSURE DE-

VICE. IT CANNOT WITHSTAND FLUSHING WATER PRESSURE. WHEN INSTALLING THE IN-LINE STRAINER

EQUIPPED WITH HALE MDT II OR MST, MAKE SURE THE IN-LINE STRAINER/VALVE ASSEMBLY IS IN THE HOSE

ON THE INLET SIDE OF THE VALVE. IF THE STRAINER IS SUBJECT TO FLUSHING WATER PRESSURE, USE

HALE FS SERIES STRAINERS.

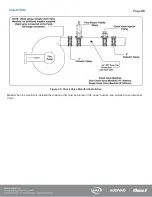

The strainer/valve assembly has 1-1/4” (32 mm) NPT female threaded ports. Fittings are supplied for connection to the

following inside diameter hose, depending on the viscosity of foam concentrates used (

).

❑

3/4” (19 mm)

❑

1.00” (25 mm)

❑

1-1/4” (32 mm)

Use 3/4” (19 mm) inside diameter hose for Class “A” foam and a 1.00” (25 mm) inside diameter hose for Class “B” foams.

For high viscosity Class “B” foam concentrates use 1-1/4” (32 mm) or 1-1/2-in (38 mm) inside diameter hose (

).

A bracket is included to permit installation on the apparatus.

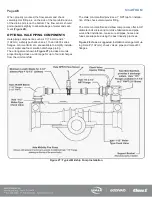

Figure 33: In-Line Strainer/Valve Installation

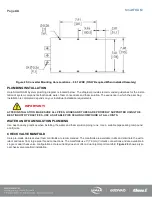

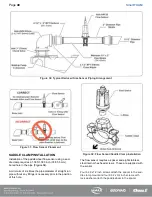

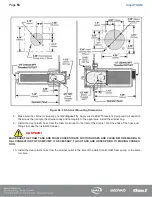

To Install the In-Line Strainer/Valve Assembly

1. Choose a location on the apparatus that allows gravity feed from the foam tank to the strainer inlet

and

from the

strainer outlet to the foam pump suction connection.

Notes: When selecting the strainer location, make sure there is sufficient space above and below the strainer.

❑

A minimum of 5” (127 mm) below for removal of the strainer basket and screen for cleaning

❑

2” (51 mm) above to permit operation of the service valve

2.

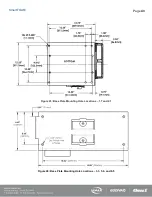

Mark 4 holes to mount the foam strainer bracket. Drill tapped holes for 1/4”-20 UNC screws (#7 drill for

¼-20 UNC tap)...or...drill clearance holes for 9/32” (7 mm) for 1/4”-20 UNC screws. (Refer to

.)

Summary of Contents for MiniCAFS 2.1A

Page 3: ...Page 2 SmartFOAM NOTES...

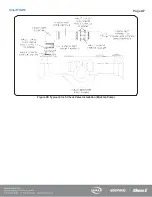

Page 16: ...Page 15 SmartFOAM SYSTEM DIAGRAM Figure 6 Typical Hale SmartFOAM 2 1A and 1 7AHP System...

Page 17: ...Page 16 SmartFOAM Figure 7 SmartFOAM 3 3 5 0 6 5 Single Tank System with In line Strainer...

Page 18: ...Page 17 SmartFOAM Figure 8 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandIn lineStrainer...

Page 19: ...Page 18 SmartFOAM Figure 9 SmartFOAM 3 3 5 0 6 5 Single Tank withMSTandFSSeriesStrainer...

Page 20: ...Page 19 SmartFOAM Figure 10 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandIn lineStrainers...

Page 21: ...Page 20 SmartFOAM Figure 11 SmartFOAM 3 3 5 0 6 5 Dual Tank withMDTIIandFSSeriesStrainer...

Page 22: ...Page 21 SmartFOAM Figure 12 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandIn lineStrainers...

Page 23: ...Page 22 SmartFOAM Figure 13 SmartFOAM 3 3 5 0 6 5 Dual Tank withADTandFSSeries Strainers...

Page 48: ...Page 47 SmartFOAM Figure 28 Typical 4 Inch Check Valve Installation Midship Pump...

Page 59: ...Page 58 SmartFOAM Figure 43 ADT Option Air Hose Connections Part 2...

Page 68: ...Page 67 SmartFOAM Figure 55 Top Mount Low Level Sensor Assembly...

Page 77: ...Page 76 SmartFOAM NOTES...

Page 90: ...89 Page 89 SmartFOAM NOTES...