Service Manual

Model No:

Issue

Rev.

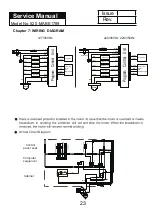

4-6. Usage of oper

11

A

C

D

E

B

Display

Flashing

Lighting

Process

Remaining Minutes

Child

Lock

Adjust

Start/Pause

Power

Cycle

Normal

Strong

Quick

Delicate

Wool

Delay

Water Level

Wash Time

Rinse Times

Spin Time

Warm

Cool

Cold

Hot

Water

Temp

Soak

Deep Clean

Air Dry

B

“

Cycle ”button

Wool

Machine washable

woolen items

Cycle

Deep clean

Delicate

Air Dry

Strong

Soak

Use this cycle for normally soiled

cottons and mixed fabric loads.

Use this cycle for heavily soiled

durable garments.

Washing for light-soil

saving

laundries

To clean very dirty

clothes

Quick washing for normal laundries

Normal

Flashing

Lighting

This cycle is suitable for soiled

items which require soak

Dries the laundries to

avoid the growth of

mildew

Note:“Air Dry” program running time is 60 minutes. The purpose is to dry the

laundries ,at the same time can dry the outer tub and the inner tub, which can

avoid growing mildew on the outer tub and the inner tub.

The max drying capacity of the laundries is 1.5kg.

F

A “Power” button

To adjust the water level, wash time, rinse times

D

Adjust ” button

spin time and delay time.

Press the “Water Temp”button to select you wash temperature.

C

Water Temp ” button

Power

Power

Start/Pause

520-MABE1789