Provide a level concrete slab. To prevent transmission of noise or vibration, slab should not be connected

to building structure. Some sort of sound-absorbing material should be placed between the condenser

and the slab. A good material to use is rubber and cork pad.

For rooftop application, make sure the building construction can support the weight and that proper

consideration is given to the weather-tight integrity of the roof. The condensing unit contains moving

parts and can vibrate. Therefore, sound is also a consideration in rooftop applications.

6

! WARNING

- Install the unit securely in a place that can bear the weight of the unit. When installed

in an insufficiently strong place, the unit could fall causing injury.

6.2.UNIT CLEARANCES

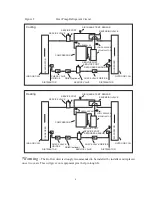

The minimum clearances for the unit are illustrated in

Figure 3

. Condenser air enters from three sides.

Air discharges upward from the top of the unit. Refrigerant tube and electrical connections are made

from the service access area. The most common application will find the unit best located about 10"

from back wall with connection side facing the wall. This application minimizes exposed tubing and

wiring, minimizing the space for youngsters to run around the unit with subsequent damage to the

tubing or wiring.

In more confined application spaces, such as corners provide a minimum of 10" clearance on all air

inlet sides. For service access to the compressor and control box, allow 18" minimum clearance. Ensure

top is unobstructed. If units are to be located under an overhang, there should be a minimum of 36"

clearance and provision made to deflect the warm discharge air out from the overhang.

In order to have an unrestricted air flow, owners should be advised to avoid lawn mower discharge

toward the unit depositing debris on the fin coil surface reducing the unit efficiency.

6.3.REFRIGERANT PIPING

The refrigerant piping is very important as it affects the proper operation and efficiency of the air

conditioning system. Note the following guidelines:

10" Min.

Service Access

18" Min.

Figure 3

10" Min.

10"

10"

Service Access

18" Min.

Summary of Contents for HR18D2VAR

Page 1: ...No 0010578573 HR18D2VAR HR24D2VAR HR30D2VAR 13 SEER 1 5 to 3 0 Ton HR36D2VAR ...

Page 13: ...5 5 ...

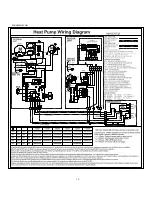

Page 17: ...HR18 36D2VAR 15 YL GR ...

Page 18: ...Made in P R C ...