16

RECOMMENDATION:

We recommend you to install the

metal box containing the electronic components at a distance

of at least 10 cm from the ground and sufficiently from all the

sources of heat (e.g.: side of an oven or hob).

If the instructions for installation for the gas hob specify a

greater distance, this must be adhered to.

Electrical connection

The hood must be connected to the mains supply by qualified

and trained technicians.

The mains power supply must correspond to the rating

indicated on the plate situated inside the hood. If provided with

a plug connect the hood to a socket in compliance with current

regulations and positioned in an accessible area, after

installation. If it not fitted with a plug (direct mains connection)

or if the plug is not located in an accessible area, after

installation, apply a double pole switch in accordance with

standards which assures the complete disconnection of the

mains under conditions relating to over-current category III, in

accordance with installation instructions.

Warning!

Before re-connecting the hood circuit to the mains

supply and checking the efficient function, always check that

the mains cable is correctly assembled.

Note:

in applications with a remote GME motor, connect the

cable of the motor unit in the designated terminal board

located inside the plastic box in the downdraft's wiring. Make

sure you follow the colours of the cables during the

connection.

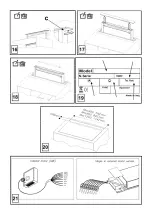

Fig. 21

Caution! Do not cut the cable between the hood and the

engine to avoid losing your right to warranty!

Mounting

Before starting to mount the appliance, make sure that no

component is damaged, otherwise contact the dealer and stop

mounting. In addition, read all the instructions below carefully.

•

Use an air outlet pipe no longer than 5 metres.

•

Limit the number of curves in the duct since each curve

reduces the suction effectiveness equivalent to 1 linear

metre. (E.g.: if two 90° curves are used, the duct should

be no longer than 3 metres).

•

Avoid drastic changes of direction.

•

Use a duct with 150mm diameter constant for the whole

length.

•

Use a duct made of standard complying material.

•

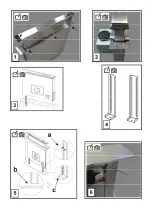

Remove the safety shim highlighted in the picture (

Fig. 1-

2

) at the end of the installation.

•

In case of failure to observe the instructions above, the

supplier can not be held responsible for capacity or noise

problems and no warranty will be granted.

•

Before making the hole, make sure that the inside of the

cabinet, near the hood housing area, does not have the

structure of the cabinet or other particulars which may

cause problems for the proper installation. Make sure

that the overall dimensions of the hood and the hob ae

compatible with the cabinet and therefore the installation

is feasible.

•

Perform, in the back of the hob, a rectangular hole with

the following dimensions:

(Fig. 20)

Hood 60cm Model:

542x100mm.

Hood 90cm Model:

842x100mm.

Hood 120cm Model:

1142x100mm

•

Install the hood in the hole made, inserting it from above,

as shown (

Fig. 3

). In case of version with motor on

board, it is necessary to remove the suction unit before

inserting the product into the cabinet.

•

Fix the hood inside the cainet using the special brackets

supplied (

Fig. 4

). Start mounting the brackets in the lower

part of the hood (

Fig. 5a

) making sure that there is a

distance of 2 mm between the lower part of the bracket

and the cabinet bottom (

Fig. 5b

). This distance allows

the traction of the product downwards on fixing, (

Fig. 5c

),

so that the stainless steel frame adheres perfectly on the

worktop.

•

Before inserting the screws into the cabinet, make sure

that the product is perfectly perpendicular to the worktop.

• After completing the installation and connecting the

product to the power supply, lift the hood and remove the

door lock (

Fig. 6

).

•

In case of version with motor on board start mounting the

motor unit directing the air outlet to the chosen position

downwards or upwards (

Fig. 7b

). The motor can be

installed on both the front side and the back one of the

hood. Once the installationof the motor has been

comleted, start mounting the duct for the air outlet.

•

In case of version with external motor put the suction unit

(external motor) in a suitable area and arrange the air

outlet duct. Start mounting the air outlet duct between the

external motor and the hood. Select the air outlet among

the five possibilities (

Fig. 7a

) and install the union

supplied.

•

Put the metal box containing the electronic components

in an easily accessible area for any assistance

operations (

Fig. 8

), connecting the electric connectors of

the same to the hood: pushbutton panel connector (

Fig.

9a

), 9-pole connector (

Fig. 9b

), neon connector (

Fig. 9c

)

•

In case of installation with remote motor,connect the

power unit cable to the special connector placed on the

electronic components box (

Fig.10a

)

•

Connect the product to the power supply