The PVM Utility is necessary for this procedure. To download the PVM Utility, refer to

Download the

PVM utility

on page 27.

This is the general procedure to update firmware for the meter and sensor. To update the sensor

firmware, the sensor must be connected to the meter.

1.

Double-click the PVM Utility desktop icon.

2.

Push the power button on the meter. When the meter self-test is complete, push

OK

.

3.

In the Main Menu, select Setup, then push

OK

.

4.

Select USB>CDC, then push

OK

.

5.

Connect the USB cable to the portable meter and the PC.

6.

In the PVM Utility window, select Connect.

7.

In the drop-down menu, select the PVM (COM X) port, where COM X is the virtual port number

assigned to the PVM by Windows. Push

OK

.

8.

In the left-side panel, select Firmware Update, then select the Meter or Sensor tab.

9.

Select the correct firmware version, then click Start.

The firmware download starts. A "Firmware update successful" message shows when the

download is complete. For meter updates, the instrument display turns off until the instrument

completes the update. Then, the instrument automatically resets and powers up again after a few

minutes. Do not try to make the instrument power on or off before the update process is

complete.

10.

In the Main Menu, select Diagnostics > About. Make sure that the firmware versions for both the

Handheld Boot and the Handheld Application are correct.

Clean the sensor

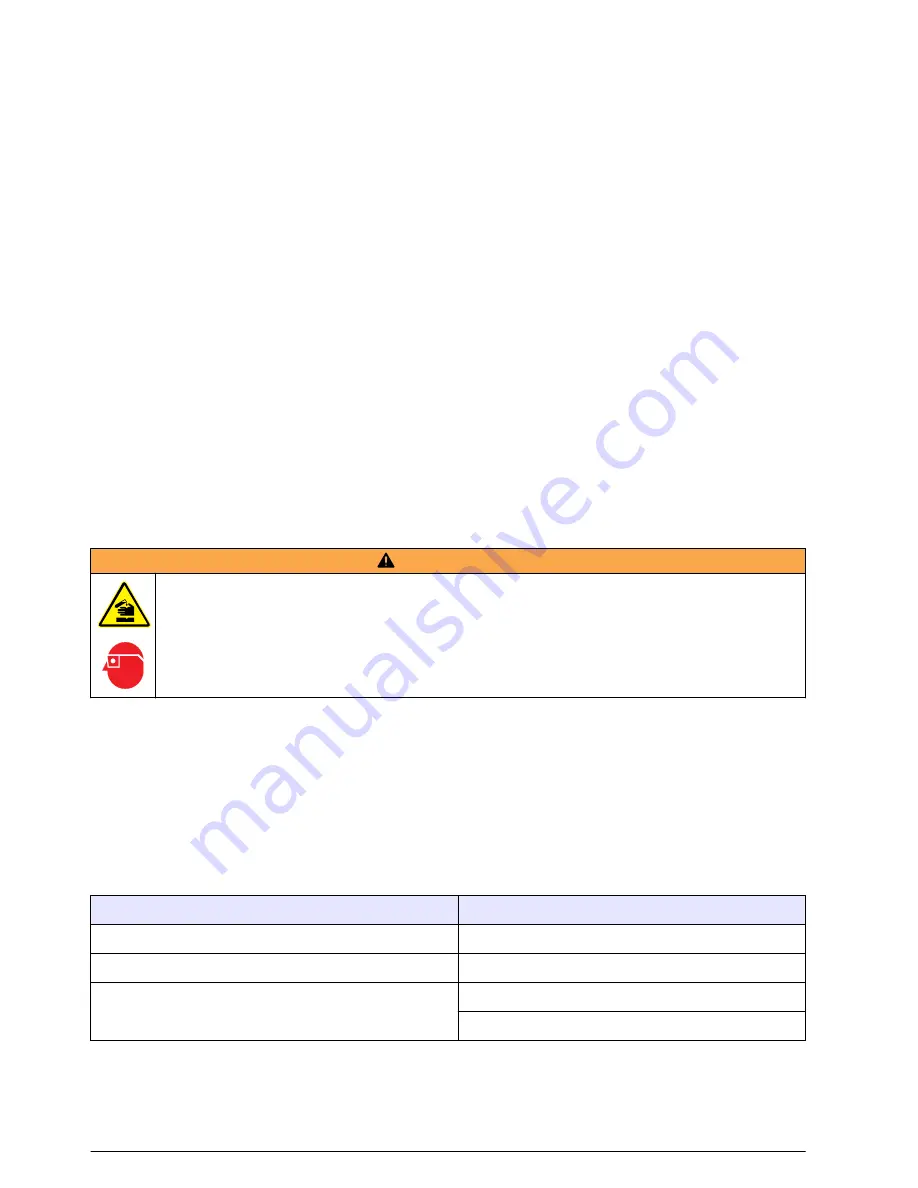

W A R N I N G

Chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective

equipment appropriate to the chemicals that are handled. Refer to the current safety data sheets

(MSDS/SDS) for safety protocols.

Clean the sensor when unexpected increases or decreases in flow or level trends occur and after

use in sandy or muddy waterways.

For heavy contamination, soak the sensor in clear water for a few minutes to help make the

contamination easy to remove.

Disconnect the sensor from the meter before it is cleaned. Use only solutions listed as acceptable in

Table 4

to clean the sensor. For sensors with a pressure cell (i.e., velocity plus depth sensors), make

sure the holes for the pressure cell chambers are washed out and clear of contamination. Rinse the

sensor with clean water before re-attaching the sensor to the assembly.

Table 4 Acceptable and unacceptable cleaning solutions

Acceptable

Do not use

Dish detergent and water

Concentrated bleach

Window cleaner

Kerosene

Isopropyl alcohol

Gasoline

Aromatic hydrocarbons

28

English

Summary of Contents for FH950

Page 1: ...DOC026 53 80210 FH950 04 2018 Edition 5 User Manual...

Page 2: ......

Page 38: ...36 English...

Page 39: ......