Page 5

Monitor Measurements in Real-Time

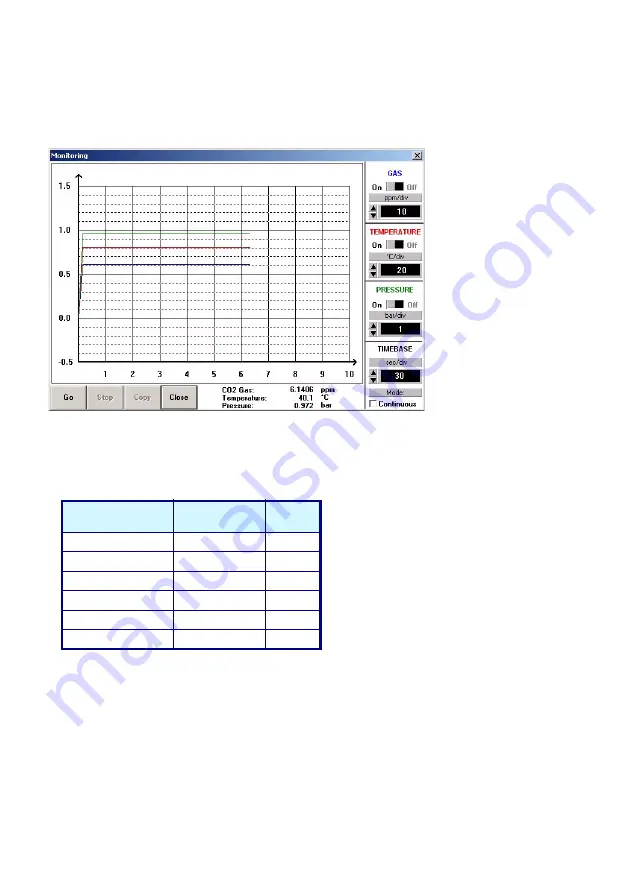

You may wish to analyze a particular sampling point via the Hach Ultra 3658 program's

Monitoring

menu. To use this Monitoring chart, the analyzer must be connected to your PC.

Choose

Monitoring

from

the Hach Ultra 3658 menu

to bring up a chart display.

The chart shows the gas

concentration (in blue),

temperature (in red), and

pressure (in green) as the

sample is being measured

by the 3658 instrument.

T h e c h a r t i s u p d a t e d

directly from instrument

measurements, at a rate

determined by the time

scale set in the

TIMEBASE

b o x a t t h e l o w e r r i g h t

corner of the chart.

Click the

TIMEBASE

up/

down pointers to change

t h e t i m e s c a l e o f t h e

divisions of the chart. Each division mark along the baseline (1, 2, ...10) can be made to represent from

30 seconds to 2½ hours, providing from 5 minutes to 25 hours of continuously displayed samples (as

illustrated in the table).

Click on the

Continuous

box to enable or

disable continuous charting. When this box is

checked, the chart scrolls continuously after

reaching the

10

division, and the oldest

samples are lost off the left of the chart.

When

Continuous

is not checked, the chart

stops displaying new results after reaching

t h e

1 0

d i v i s i o n , a n d a l l s u b s e q u e n t

measurements are lost.

C l i c k t h e u p / d o w n p o i n t e r s f o r e a c h

m e a s u r e m e n t v a r i a b l e (

G A S

,

TEMPERATURE

and

PRE SSURE

) t o

change the scaling of that value on the chart. The display of each measurement variable may be turned

on or off by choosing the appropriate

On

or

Off

switch.

A running display of latest sample

Gas

,

Temperature

and

Pressure

is also shown in the bottom-right

corner of the chart.

Use the buttons at the bottom of the chart to control real-time monitoring. Choose

Go

to clear the chart

and start real-time monitoring,

Stop

to stop monitoring and

Copy

to copy the data from the chart as text

information to the Windows Clipboard. This information can be pasted from the clipboard into any

Windows application, such as a spreadsheet or word processor.

Choose

Close

to close the Monitoring window.

Measurement (cont)

Timebase

Updating Rate

Max.

Samples

30 Seconds/Division

5 Secs/Sample

60

1 Minute/Division

5 Secs/Sample

120

10 Minutes/Division

5 Secs/Sample

1,200

30 Minutes/Division

9 Secs/Sample

2,000

1 Hour/Division

18 Secs/Sample

2,000

2.5 Hours/Division

45 Secs/Sample

2,000

Summary of Contents for ORBISPHERE 3658

Page 1: ...Operator Quick Guide ORBISPHERE 3658 Revision A 28 04 2008 ...

Page 15: ...Page 15 ...

Page 16: ......