Cryogenic Valves

3

C47C, FC47C, FC47W

6.1.3.

All Habonim cryogenic valves are uni-directional and must

be installed for flow in one direction as indicated by the flow

arrow welded on the body and bonnet pad. Usually the arrow

points to the shutoff direction of the valve. In some cases

where it is not clear, relate to the arrow head as the low

pressure side and the arrow tail as the high pressure side.

BODY

BALL

SEAT

PRES.

SIZE

****

****

****

****

**

***

******************

Habonim logo

Body material

Seat material

Valve size

Valve description

Ball material

Work order

Max. pressure

INDUSTRIAL VALVES & ACTUATORS LTD

KFAR HANASSI, 1230500 IL

BODY

BALL

SEAT

BAR @

°C

1155

Habonim logo

Body material

Max. pressure @

Min. temperature

Min. pressure @

Max. temperature

Valve description

CE mark

Ball material

Seat material

Valve size

Year manufacture

DN

P.O.

YR

BAR @

°C

once in 6 months for fully open/close position.

5.8.

Ball valves should be operated for at least two complete

cycles before installing or returning to storage.

6. INSTALLATION

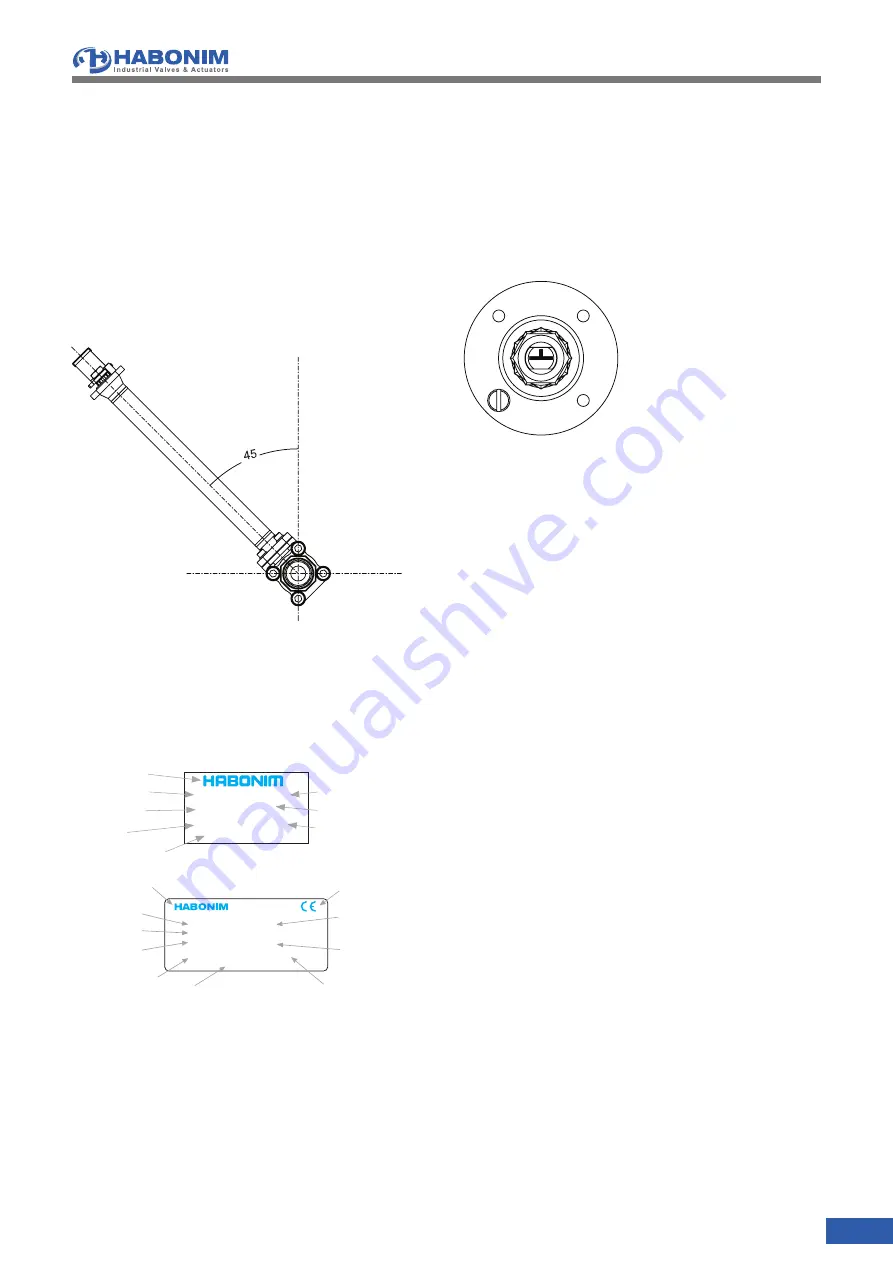

Caution: DO NOT install Cryogenic valves with the extended

bonnet tilted more than 450 from the upright vertical position.

(see figure 1)

FIGURE 1

Valve Tilting Limitation

6.1 General

6.1.1.

Keep the valve in its polyethylene bag until ready for use.

Check the valve nameplate for identification of materials

(see Figure 2)

.

FIGURE

4.1.2.

When the valve is in the closed position the ball relief hole

will be seen in the upstream port of the valve as indicated

by the arrow. The stem head has an engraved "T" mark

identifying the ball port and the pressure relief hole direction

(See Figure 3)

.

FIGURE 3

Valve Top View

4.1.4.

When the valve is in the closed position the ball relief hole will

be seen in the upstream port of the valve as indicated by the

arrow. The stem head has an engraved "T" mark identifying

the ball port and the pressure relief hole direction

(See

Figure 3)

.Inspect the valve interior through the end ports to

determine that it is clean and free from foreign matter.

6.1.5.

Cycle the valve and inspect any functionally significant

features.

6.1.6.

Read all the literature, and note any special warning tags or

plates attached to the valve.

6.1.7.

During installation, it is recommended that the valve ball be left

in the open position to prevent possible damage to the ball.

6.2 Threaded End Valves

6.2.1.

Valves with screwed ends should be treated as a single unit

and should not be dismantled when installing to the pipeline.

6.2.2.

Before installing the valve, make sure that the threads on the

mating pipe are free from excessive grit, dirt or burrs.

6.2.3.

When tightening the valve, apply a pipe wrench or spanner

to the end connector closest to the pipe being worked, using

standard piping practices.

6.2.4.

Use appropriate joint sealing materials in correct quantities.

6.2.5.

If "back-welding" is required on screwed valves, refer to the

instructions for Weld End valves or to the "Habonim Welding

Instructions" bulletin.

6.3 In-line welding

6.3.1.

Cryogenic valves suitable for in-line welding are designed

with extended ends. Habonim ends identification code XBW,

ETO. (Socket welding is not recomended for Cryogenic use)

6.3.2.

Welding of valves shall be performed by a qualified welder

according to the ASME Boiler Construction Code Section

IX. For valves to be welded within the EEA, refer to the

requirements of ESR 3.1.2 of the Pressure Equipment

Directive 97/23/EC.

6.3.3.

Valves must be in the fully open position to protect the ball

and seats from excessive temperatures during the welding

procedures.

6.3.4.

Automated Valves in the "Fail Close" position should be