GB

6

4. Maintenance work

WARNING

Before starting any cleaning work, the stove must be cool down! The mains plug must be pulled out of

the power supply socket (always in advance)!

WARNING

Devices that are not maintained in accordance with our specifications must not be operated. Failure to

observe this point will invalidate all guarantee claims.

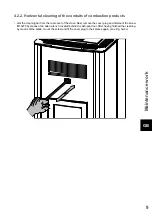

4.1. Cleaning of the ash pan - once a week

WARNING

The frequency of maintenance in turn depends to a large extent on the pellet quality (ash content). Quality

pellets have a low ash content of about 0.2-0.3%. However, if the ash content is higher (0.5% and over), the

interval from maintenance to maintenance is reduced and the accumulation of ash increases by 2 or 3 times.

Summary of Contents for HSP 6 537.08-WT RLU/PGI

Page 4: ......

Page 6: ...Dimensions GB 2 2 Dimensions 2 1 Dimensions...

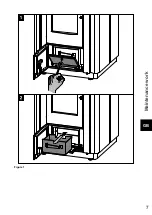

Page 11: ...Maintenance work GB 7 Figure 1...

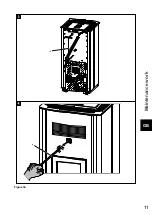

Page 14: ...Maintenance work GB 10 Figure 3a...

Page 15: ...Maintenance work GB 11 Figure 3b...

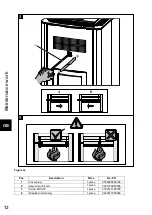

Page 18: ...Maintenance work GB 14 Figure 4...

Page 19: ...Maintenance work GB 15 Figure 5 Removing the side wall...

Page 26: ...Circuit diagram GB 22 6 Circuit diagram Circuit diagram IO 33 6...

Page 28: ......