6

•

The equipment room is at least 3 m (9.84 ft) high.

•

Reserve a minimum of 1 m (3.28 ft) of clearance between the rack and walls or other devices.

•

The dimensions of the rack are sufficient for the chassis. For more information about chassis

specifications, see "

Appendix A Chassis views and technical specifications

."

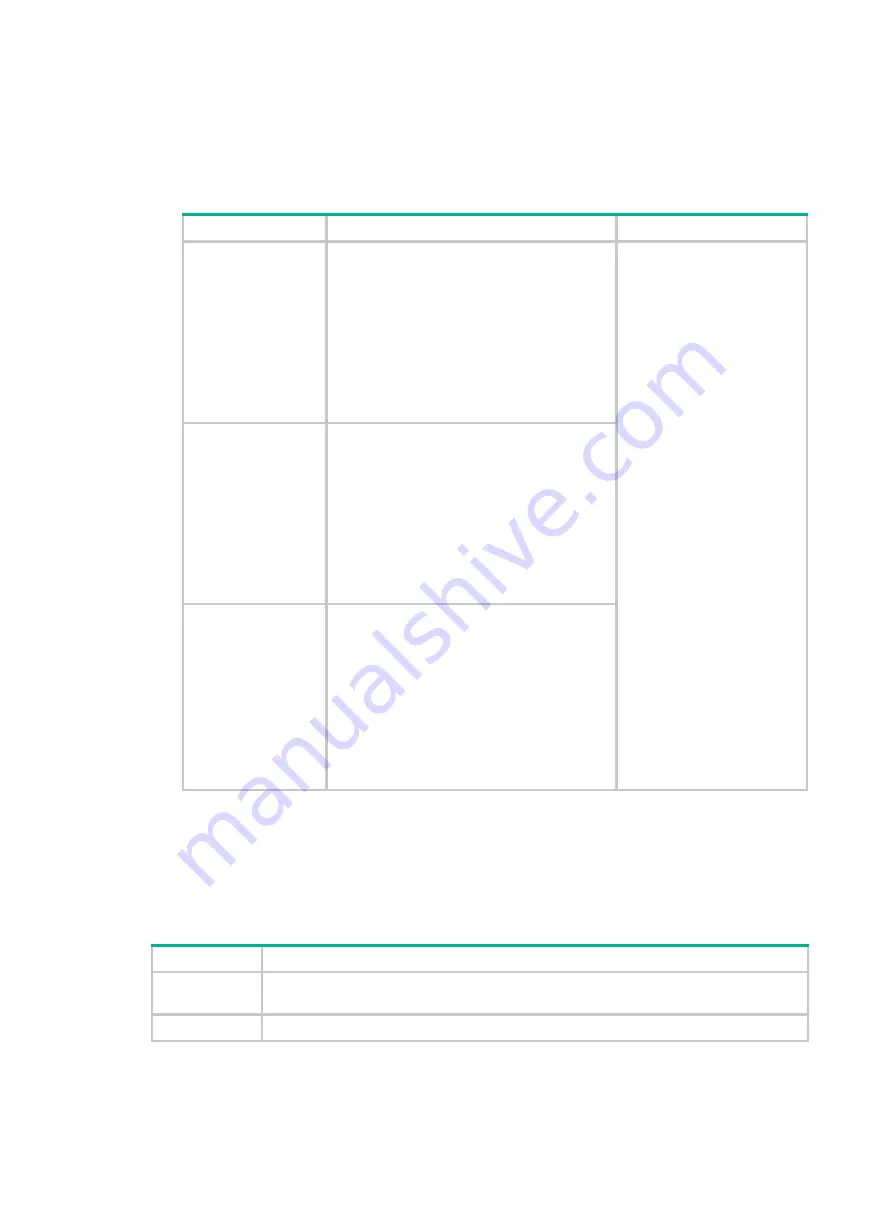

Table 5 Device dimensions and rack requirements

Model

Chassis dimensions

Rack requirements

M9006

•

Height

—353 mm (13.90 in)/8 RU

•

Width

—440 mm (17.32 in)

•

Depth

—757 mm (29.80 in)

{

660 mm (25.98 in) for the chassis

{

95 mm (3.74 in) for the cable

management bracket at the front of

the chassis

{

24 mm (0.94 in) for the switching

fabric module ejector levers at the

rear of the chassis

•

A minimum of 1.0 m

(3.28 ft) in depth

(recommended)

•

A minimum of 130 mm

(5.12 in) between the

front rack post and the

front door

•

A minimum of 690 mm

(27.17 in) between the

front rack post and the

rear door

M9010/M9010-GM

•

Height

—886 mm (34.88 in)/20 RU

•

Width

—440 mm (17.32 in)

•

Depth

—757 mm (29.80 in)

{

660 mm (25.98 in) for the chassis

{

95 mm (3.74 in) for the cable

management bracket at the front of

the chassis

{

24 mm (0.94 in) for the switching

fabric module ejector levers at the

rear of the chassis

M9014

•

Height

—797 mm (31.38 in)/18 RU

•

Width

—440 mm (17.32 in)

•

Depth

—757 mm (29.80 in)

{

660 mm (25.98 in) for the chassis

{

95 mm (3.74 in) for the cable

management bracket at the front of

the chassis

{

24 mm (0.94 in) for the switching

fabric module ejector levers at the

rear of the chassis

Installation tools

lists the tools and equipment that you might use during installation, and all of them are user

supplied. Prepare them before installation.

Table 6 Tools and equipment list

Category Tool

Measuring and

marking tools

Long tape, ruler (of 1 meter, or 3.28 ft), gradienter, marker, chalk line, and pencil

Drills

Hammer drill, electric drill, and several auxiliary drill bits