59

Appendix B LEDs

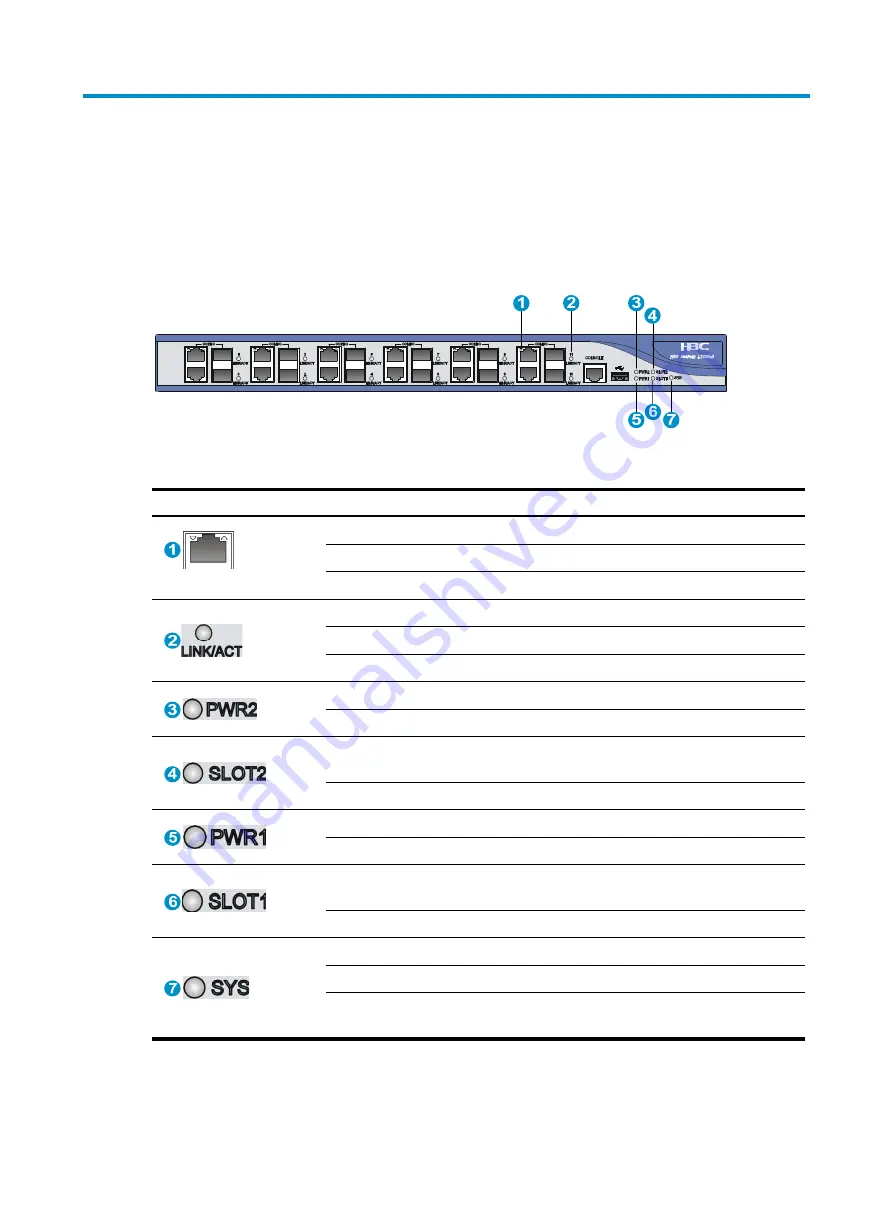

Panel LEDs

Figure 45

F1000-A-EI LEDs

Table 26

LED description

LED Status

Description

(yellow/green)

Off

No link is present on the corresponding port.

Steady green

A 1000 Mbps link is present on the port.

Steady yellow

A 10/100 Mbps link is present on the port.

(green)

Off

No link is present.

On

A link is present.

Flashing

Data is being transmitted or received on the port.

(green)

Off

No power input or power module 2 is not present.

On

Power module 2 is operating correctly.

(green)

Off

No interface module is present in slot 2 or the

interface module is faulty.

On

The interface module in slot 2 is operating correctly.

(green)

Off

No power input or power module 1 is not present.

On

Power module 1 is operating correctly.

(green)

Off

No interface module is present in slot 1 or the

interface module is faulty.

On

The interface module in slot 1 is operating correctly.

(green)

Off

No power input or the power module is faulty.

Slow flashing (1 Hz)

The L1000-A is operating correctly.

Fast flashing (8 Hz)

The application software is being loaded, or the

L1000-A is not working.