2-20

Connecting the power cord for a PSR150-D1 or PSR560-56D

power supply

CAUTION:

•

Connect the other ends of the wires for a PSR150-D1 power supply to a –48 VDC power source,

with the negative wire (

–

or

L–

) to the negative terminal (

–

) and the positive wire (

+

or

M/N

) to the

positive terminal (

+

).

•

To use a –48 VDC power source to supply power to the power supply, use the DC power cord

supplied with the power supply.

•

To use an H3C RPS (–54 VDC) to supply power to the power supply, use a compatible RPS

power cord to connect the RPS to the power supply.

•

The power cord color code scheme in

is for illustration only. The cable delivered for

your country or region might use a different color scheme. When you connect the power cord,

always identify the polarity symbol on its wires.

The power cord connection procedure is the same for the PSR150-D1 and PSR560-56D power

supplies. The following procedure uses a PSR150-D1 power supply as an example.

To connect the power cord for a PSR150-D1 power supply:

1.

Wear an ESD wrist strap and make sure it makes good skin contact and is reliably grounded.

2.

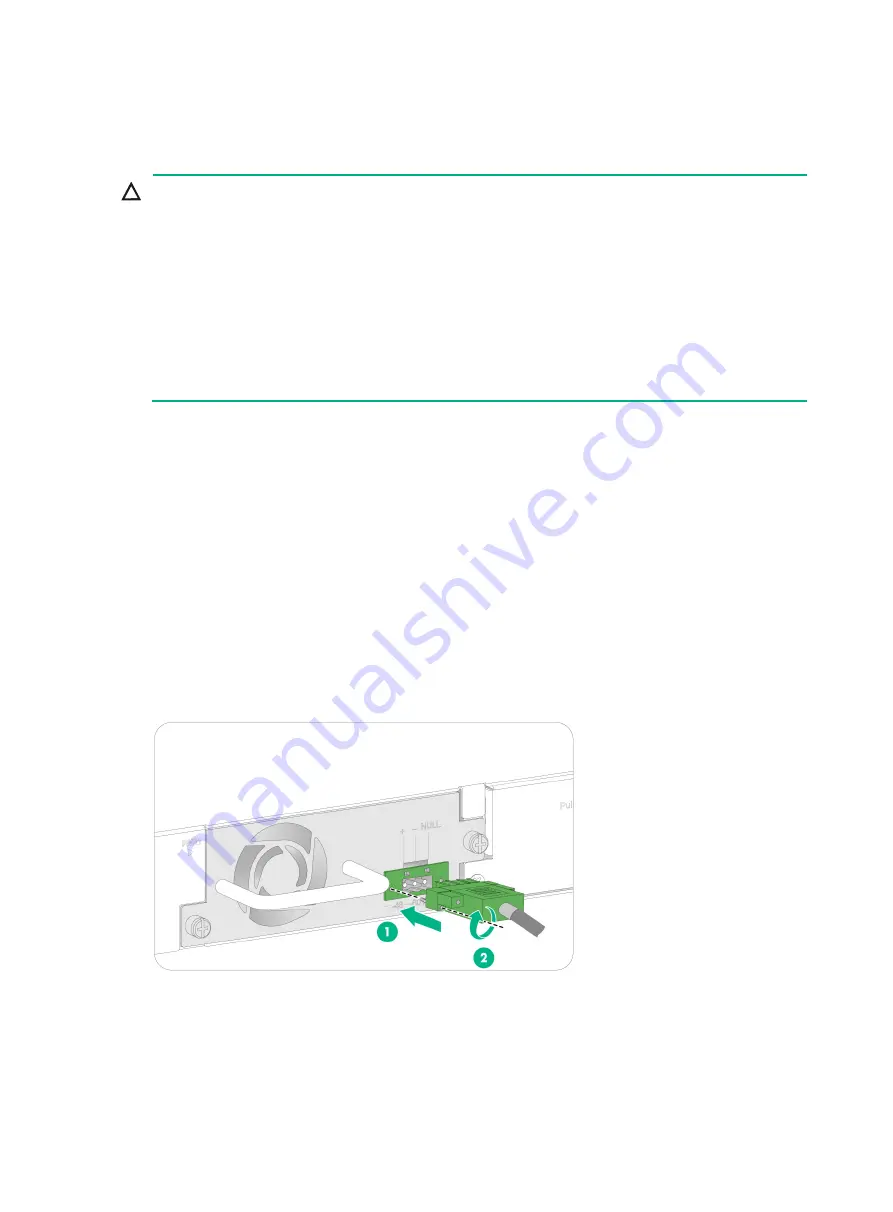

Unpack the power cord, correctly orient the plug at one end of the cable with the power

receptacle on the power supply, and insert the plug into the power receptacle (see callout 1 in

The power receptacle is foolproof. If you cannot insert the plug into the receptacle, re-orient the

plug rather than use excessive force to push it in.

3.

Tighten the screws on the plug with a flat-blade screwdriver to secure the plug in the power

receptacle (see callout 2 in

4.

Connect the two wires at the other end of the power cord to a –48 VDC power source or an

RPS.

Figure2-29 Connecting the power cord for a PSR150-D1 power supply