1-3

•

The installation site has a good ventilation system.

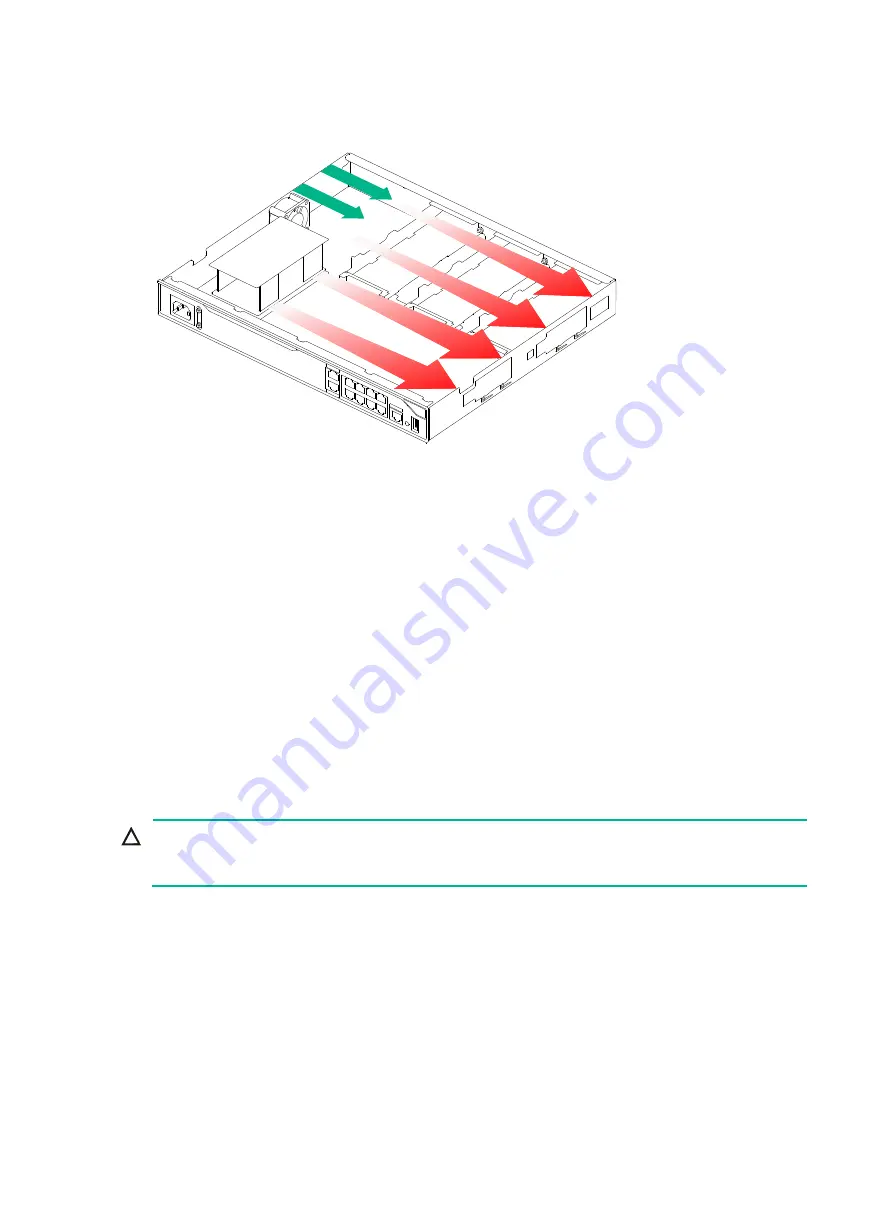

Figure1-1 Airflow through the ICG2000D-EI chassis

ESD prevention

Preventing electrostatic discharge

To prevent electrostatic discharge (ESD), follow these guidelines:

•

Make sure the device and the floor are reliably grounded.

•

Take dust-proof measures for the equipment room.

•

Maintain the humidity and temperature levels in the acceptable range.

•

Always wear an ESD wrist strap and an ESD garment when touching a circuit board or

transceiver module.

•

Place the removed interface module on an antistatic workbench with the circuit board upward,

or put it in an antistatic bag.

•

Touch only the edges instead of electronic components on the circuit board when you observe

or move a removed interface module.

Attaching an ESD wrist strap

CAUTION:

Use a multimeter to check the resistance of the ESD wrist strap for safety. The resistance reading

should be in the range of 1 to 10 megohm (Mohm) between a human body and the ground.

No ESD wrist strap is provided with the device. Prepare one yourself.

To attach an ESD wrist strap:

1.

Wear the wrist strap on your wrist.

2.

Lock the wrist strap tight around your wrist to maintain good contact with the skin.

3.

Secure the wrist strap lock and the alligator clip lock together.

4.

Attach the alligator clip to the rack or workbench where the device is installed.