English (GB)

20

8.2 Pump controllers

The following LC and LCD pump controllers are available for level

control:

LC controllers are for one-pump-installations and LCD controllers

are for two-pump installations.

• LC 107 and LCD 107 with air bells

• LC 108 and LCD 108 with float switches

• LC 110 and LCD 110 with electrodes.

In the following description, "level switches" can be air bells, float

switches or electrodes, depending on the pump controller

selected.

The

LC

controller is fitted with two or three level switches:

One for start and the other for stop of pump. The third level

switch, which is optional, is for high-level alarm.

The

LCD

controller is fitted with three or four level switches:

One for common stop and two for start of the pumps. The fourth

level switch, which is optional, is for high-level alarm.

When installing the level switches, observe the following points:

• To prevent air intake and vibrations install the

stop level

switch

in such a way that the pump is stopped before the

liquid level is lowered below the top of the cable entry.

• In tanks with one pump, install the

start level switch

in such a

way that the pump is started at the required level; however,

the pump must always be started before the liquid level

reaches the bottom inlet pipe to the tank.

• In tanks with two pumps, the

start level switch

for pump 2

must start the pump before the liquid level reaches the bottom

inlet pipe to the tank, and the start level switch for pump 1

must start this pump correspondingly earlier.

• If installed, always install the

high-level alarm switch

about

10 cm above the start level switch; however, the alarm must

always be given before the liquid level reaches the bottom

inlet pipe to the tank.

For further information, see the installation and operating

instructions for the pump controller selected.

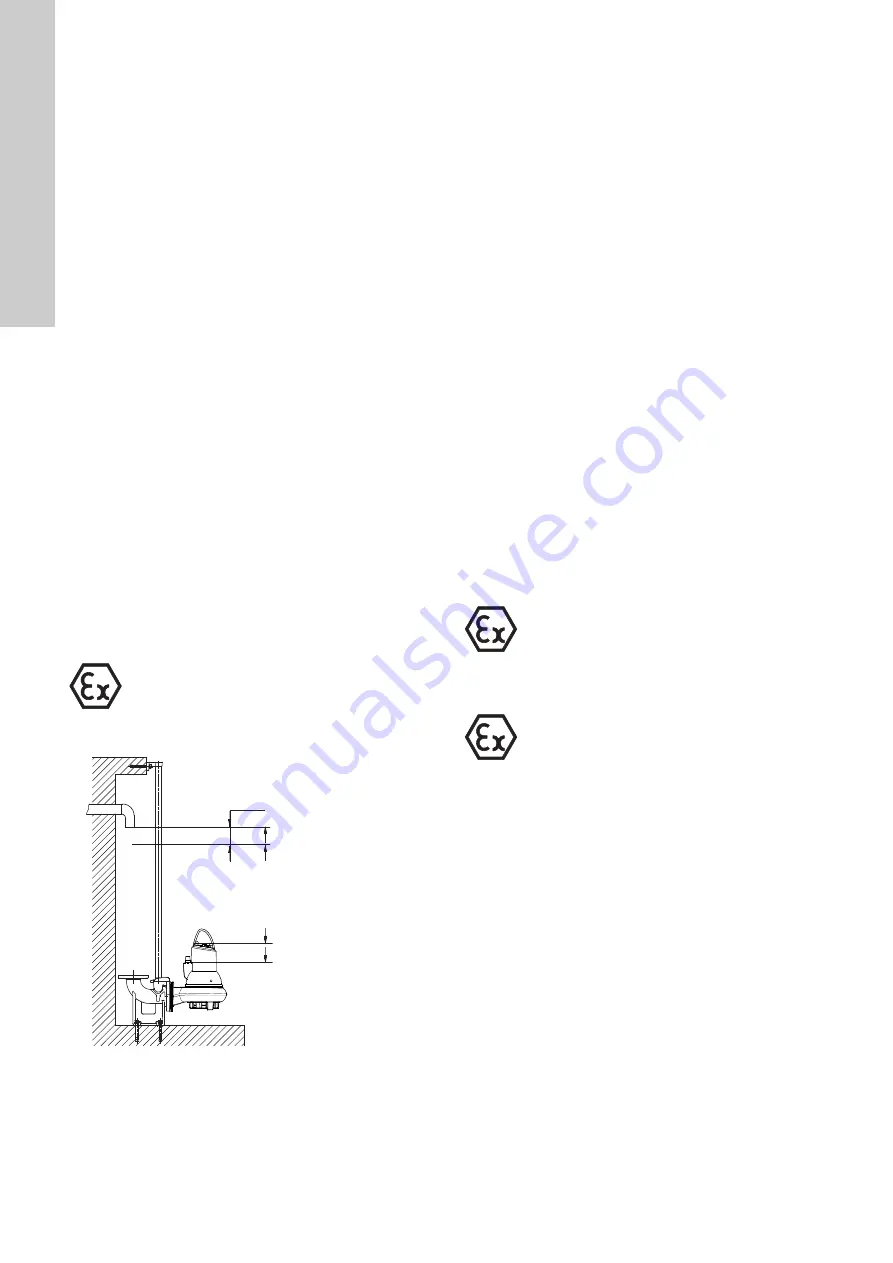

Fig. 10

Start and stop levels

Make sure that the effective volume of the tank does not become

so low that the number of starts per hour exceeds the maximum

permissible number. See section

8.3 Thermal switch, Pt1000 and PTC thermistor

All SL1 and SLV pumps have thermal protection incorporated in

the stator windings.

Pumps without sensor

Pumps without sensor have a thermal switch or a PTC thermistor.

Via the pump controller safety circuit, the thermal switch will stop

the pump by breaking the circuit in case of overtemperature

(approx. 150 °C). The thermal switch will reclose the circuit after

cooling. For pumps equipped with a PTC thermistor, connect the

thermistor to either the PTC relay or the I/O module to break the

circuit at 150 °C.

The maximum operating current of the thermal switch is 0.5 A at

500 VAC and cos

φ

0.6. The switch must be able to break a coil in

the supply circuit.

Pumps with sensor

Pumps with sensor have either a thermal switch and a Pt1000

sensor or a PTC thermistor in the windings, depending on the

installation site.

Via the pump controller safety circuit, the thermal switch or the

thermistor will stop the pump by breaking the circuit in case of

overtemperature (approx. 150 °C). The thermal switch or the

thermistor will reclose the circuit after cooling.

The maximum operating current of both the Pt1000 and the

thermistor is 1 mA at 24 VDC.

Non-explosion-proof pumps

When closing the circuit after cooling, the thermal protection can

restart the pump automatically via the controller. Pumps from

4 kW and up sold in Australia/New Zealand are fitted with a PTC

thermistor.

Explosion-proof pumps

Warning

Float switches used in potentially explosive

environments must be approved for this

application. They must be connected to the

Grundfos LC, LCD 108 pump controller via the

intrinsically safe LC-Ex4 barrier to ensure a safe

circuit.

TM

04 265

4 280

8

Start

Stop S1 operation

Alarm

Min. 10 cm

Stop S3 operation

Warning

The thermal protection of explosion-proof pumps

must not restart the pump automatically.

This ensures protection against overtemperature

in potentially explosive environments. In pumps

with sensor this is done by removing the short-

circuit between terminals R1 and R2 in the IO 111.

See Electrical data in the IO 111 installation and

operating instructions.

Warning

The separate motor-protective circuit breaker/

control box must not be installed in potentially

explosive environments.

Summary of Contents for SL1.100.100.40.4

Page 39: ...Appendix 39 15 Exploded drawings SLV TM04 2777 2605...

Page 40: ...Appendix 40 SL1 TM04 2778 0904...

Page 41: ...41...