English (GB)

11

8.2 CU 100 control box

The CU 100 control box incorporates a motor-

protective circuit breaker and is available with level

switch and cable.

Single-phase pumps

A run capacitor must be connected to the control

box.

For capacitor sizes, see the table below.

Start and stop levels

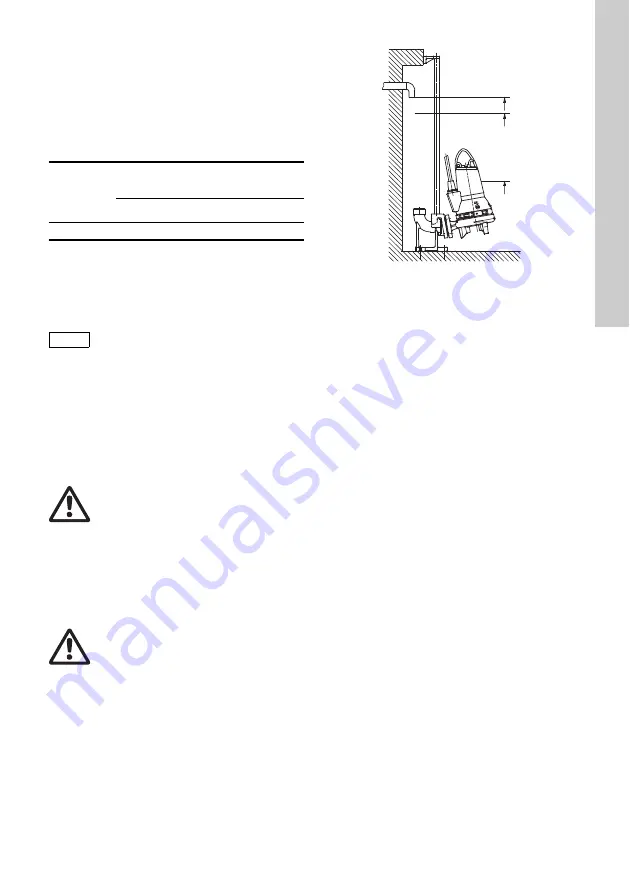

The difference in level between start and stop can be

adjusted by changing the free cable length.

Long free cable = large difference in level

Short free cable = small difference in level.

•

To prevent air intake and vibrations, install the

stop level switch in such a way that the pump is

stopped before the liquid level is lowered below

the upper edge of the clamp on the pump.

•

Install the start level switch in such a way that the

pump is started at the required level; however,

the pump must always be started before the

liquid level reaches the bottom inlet pipe to the

tank.

Fig. 6

Start and stop levels

8.3 Pump controllers

The following LC and LCD pump controllers are

available:

LC controllers are for one-pump-installations and

LCD controllers are for two-pump-installations.

•

LC 107 and LCD 107 with air bells.

•

LC 108 and LCD 108 with float switches.

•

LC 110 and LCD 110 with electrodes.

In the following description, "level switches" can be

air bells, float switches or electrodes, depending on

the pump controller selected.

Controllers for single-phase pumps incorporate

capacitors.

LC:

The controller is fitted with two or three level

switches: One for start and the other for stop of

pump. The third level switch, which is optional, is for

high-level alarm.

LCD:

The controller is fitted with three or four level

switches: One for common stop and two for start of

the pumps. The fourth level switch, which is optional,

is for high-level alarm.

Pump type

Cs, starting

capacitor

Cd, run

capacitor

[

μ

F]

[V]

[

μ

F]

[V]

SEG 150

230

30

450

Note

Both the two following points must be

observed.

Warning

The CU 100 control box must not be

used for explosion-proof applications.

See section 8.3 Pump controllers.

Warning

The pump must not run dry.

An additional level switch must be

installed to ensure that the pump is

stopped in case the stop level switch is

not operating. See fig. 6.

The pump must be stopped when the

liquid level reaches the upper edge of

the clamp on the pump.

Float switches used in potentially

explosive environments must be

approved for this application.

They must be connected to the

Grundfos DC, DCD and LC, LCD 108

pump controller via an intrinsically

safe barrier to ensure a safe circuit.

TM

02

53

89

28

02

Alarm

Start

Stop