10 / 15

A1

A2

Description

Pump is running but not as the expected pump type.

Explanation

Configuration error

In case the terminal box cannot identify the stator type, the pump will run default as a 40-120 or a 65-120.

Check/remedy

Check by means of R100 which pump type the terminal

box has registered:

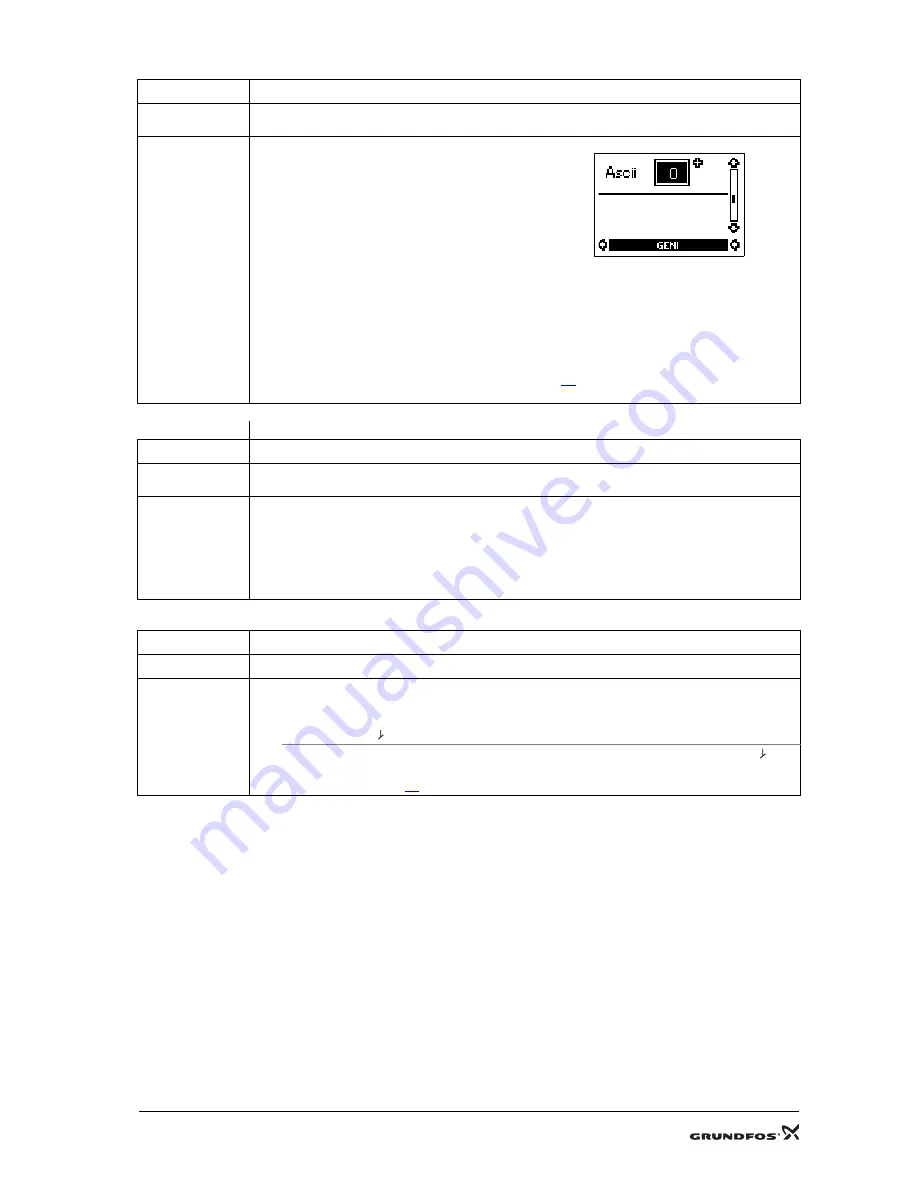

1. Switch R100 to service mode.

2. Go into the GENI menu in the display on the right.

3. Enter code 13.

R100 will now show which pump type the terminal box has registered. Check that the indication corresponds to

the actual pump type.

In case of error in the stator coding, the indication will be "ERR".

Is the pump type correct?

YES:

NO:

Fault is not due to a configuration error, but

possibly to a setting error or a system fault.

Check the stator coding according to the

drawing.

See

C2

.

In new R100 software updates the pump type can be read in the start-up display.

Description

The twin-head pump does not control its performance optimally.

Explanation

Configuration error

The terminal box uses a wrong set of parameters.

Check/remedy

As the right and the left pump head do not have the same hydraulic performance, there are a right and left set of

parameters.

Correct configuration is carried out by means of the GENI modules where the Master module must always be fit-

ted on the right pump head. (Terminals X and Q are short-circuited.) The modules must be product number

605945VO1 or higher.

If no GENI modules are used on the twin-head pumps, the configuration can be carried out by means of R100

Turbo.

Description

Pump is running at too low or high pressure.

Explanation

Setpoint setting is incorrect.

Check/remedy

1.

Is an external setpoint signal connected?

NO:

YES:

Set setpoint according to system specifications.

Check the connection to the GENI module and the external setpoint signal. Note that the termi-

nals MIN - must be closed for the setpoint setting to work.

2.

Does the pump speed vary (listen to the pump) according to the input signals on terminals 10 V - ?

YES:

NO:

Pump is OK.

Proceed to point

B1

.