004-109

The BenchMate is a heavy duty tool

designed for minimal maintenance. Like

all tools, some basic care will help it last

longer and maintain its mechanical integrity.

Keep acids and other corrosive compounds

off the BenchMate. If contact is made with

this type of material, wipe it clean and apply

a light metal protectant such as WD-40.

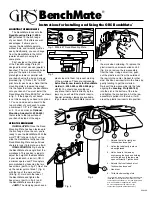

FIG. 6:

Remove the tube assembly

from the mounting collar and unscrew the

large knurled nut to disassemble the jaw

assembly from the tube. Note the condition

of the

Rubber Seal (#004-126)

located on

the jaw assembly. This seal keeps chips

and debris from entering the threaded

area at the bottom of the jaw preventing

premature thread wear. If seal appears

damaged or torn, it should be replaced.

FIG. 7:

Clean the inside of the tube

using a cloth and a wood dowel or

toothbrush handle. Check that all debris

is removed at the bottom of the tube.

FIG. 8:

Using a soft bristle brush, clean

the debris from the threaded area at the

bottom of the Jaw assembly. Take time to

clean the threads inside the knurled nut

as well and check the fit of these 2 pieces

by threading them together. Lightly oil the

clean threads, re-assemble the jaw

into the tube and snug the knurled nut.

Note: When you install the jaw assembly

back into the tube be absolutely certain

that the locating pin near the screw

threads goes back into its mating slot inside

the tube. Failure to do this may result in

damage to your BenchMate

Jaw Assembly.

FIG. 9:

Lightly oil the outside of the

tube near the top when reinserting into

the mounting collar.

Depending on the amount of use,

these maintenance procedures should

be done when you begin to notice more

force is needed to clamp the workpiece.

BenchMate

®

Maintenance

Fig. 6

Fig. 7

Fig. 8

Fig. 9