15

GROWSPAN

™

ROUND ECONOMY HIGH TUNNELS

Revision date: 10.25.21

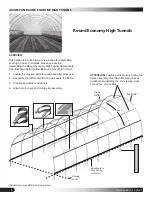

4. Once the main cover is in place and centered on the

frame, begin at the peak of one end rafter and install

the wire spring into the U-Channel to secure the cover.

ATTENTION:

Center the main cover front to back and

side-to-side to ensure that enough cover material is

present to lock into the U-Channel.

The excess cover

along each side is rolled up when the roll-up side

assemblies are installed.

The rope can remain in place to temporarily secure

the cover if needed. Remove the ropes as the cover is

secured to the frame.

Photos show installing the spring into the U-Channel on

the outside of a frame. The process is the same for the

U-Channel attached to the top of the end rafters.

5. Continue adding the spring into the U-Channel at the

top of the first end rafter. Ensure that an even amount

of the cover is exposed and maintained along the edge

of the frame as it is attached.

NOTE:

The cover material is cut longer/wider than is

required to cover the frame. For easier anchoring, allow

approximately 10" to extend past the edge of the end

rafter as the cover is anchored in place.

6. Continue down both edges of the first end rafter

until the entire length of the end of the main cover is

secured in place.

7. Stretch the cover to the other end of the building and

repeat the steps to secure the main cover in the U-

Channel.

NOTE:

Pull the cover tight as the spring is inserted into

the U-Channel.

INSTALL MAIN COVER

Gather the parts:

• Main cover

• Ropes long enough to reach over the frame (provided

by customer)

• U-Channel spring

• Box cutter or utility knife

Assembly Procedure

After the poly latch U-Channel is attached to the frame,

unpack the main cover and pull into place. Ropes or straps

are typically used to pull the main cover onto and over the

frame.

WARNING:

To prevent damage to the cover and to

prevent serious personal injury, DO NOT attempt to

install the main cover on windy or stormy days.

1. Unpack the main cover and position it at the base along

one side of the frame.

2. Make small holes along the edge of the cover at evenly

spaced intervals and tie rope to the cover. (The length

of the cover determines the number of holes that are

needed to attach the ropes.)

NOTE:

The ropes must be long enough to reach over

the top of the building to the other side. Long buildings

will require additional ropes to prevent tearing the main

cover when it is pulled into place.

3. After tying the ropes to the main cover, throw the ropes

over the top of the frame and pull the cover into place.

Cover must be centered side-to-side and end-to-end.

IMPORTANT:

To prevent damage to the main cover

during installation, additional personnel and lifts may be

needed.

Shelter shown above may be a different length than

actual shelter.