-2-

T26858/T26859 Hand Winch

Mounting

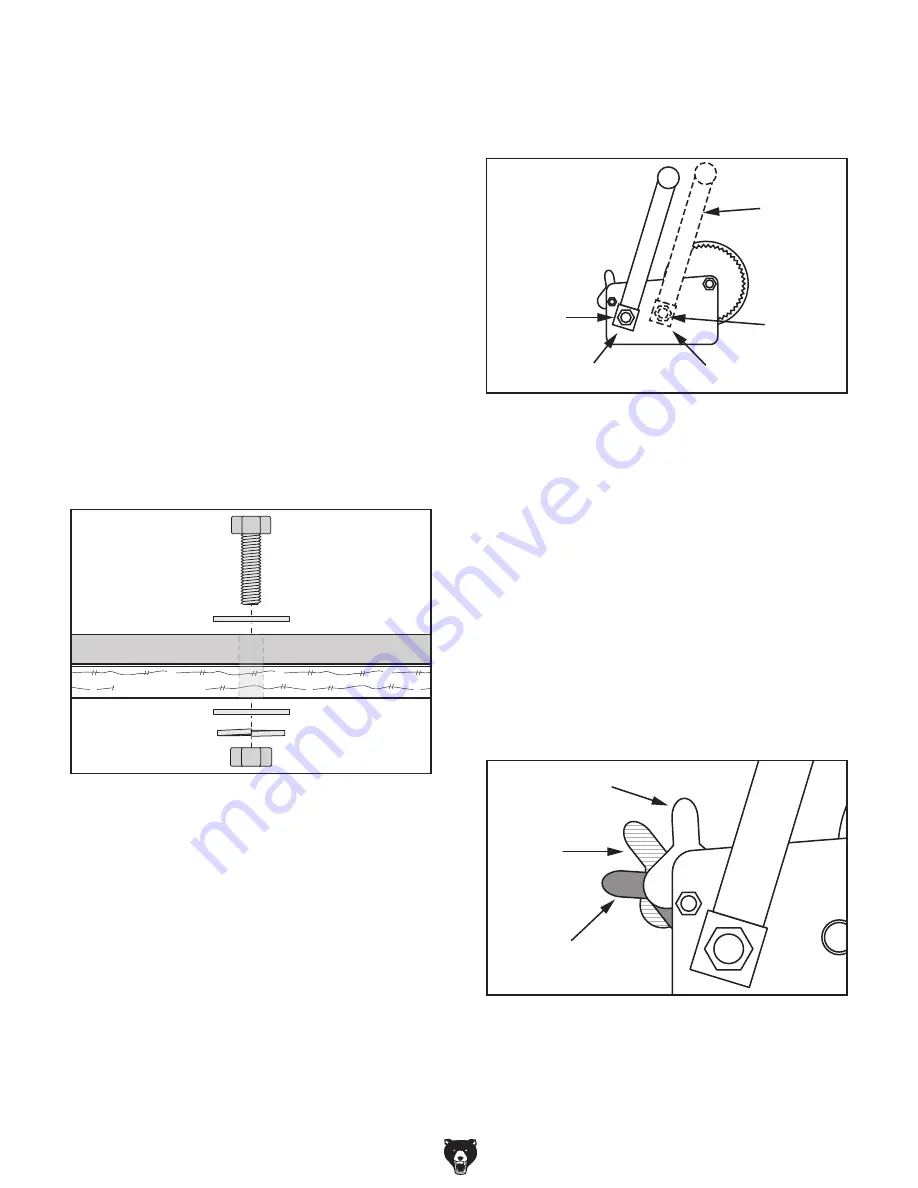

The Model T26858/T26859 has holes in the base

for mounting to most flat surfaces. The winch

must be mounted for safe and effective operation.

Before drilling into a frame or bumper component,

verify that the opposite side of the drilling area is

clear of wires, tubing, or brake lines.

To mount winch:

1. Place winch in desired position and mark

locations of mounting holes.

2. Remove winch and drill

7

⁄

16

" holes in locations

you marked in

Step 1. For safe operation, at

least three bolts should be used to secure

winch.

3. Use

3

⁄

8

" diameter mounting hardware to

secure winch to mounting surface, as shown

in

Figure 2.

Ratchet Settings

The rachet has three settings that determine

which direction the drum turns—IN, OUT, and

FREE SPIN (see

Figure 4).

Winch Base

Mounting Surface

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

Figure 2. Example of a "Through-Mount" setup.

Crank Attachment

Use a 22mm wrench to secure the crank on either

the low- or high-torque axle (see

Figure 3).

Crank

High-Torque

Axle

Low-Torque

Axle

Retaining

Plate

Lock Nut

Figure 3. Crank attachment options.

OUT

IN

FREE

SPIN

Figure 4. Ratchet settings.

The low-torque axle provides faster winching but

requires more effort, and is typically used for light

loads.

The high-torque axle requires less effort and pro-

vides slower winching, and is typically used for

heavier loads.

Refer to

Specifications on Page 1 for the gear

ratios for each axle option.