T1227/28/29 Magnetic Chuck (Mfd. Since 09/17)

-5-

Clamping Workpiece

Before any operation can be safely performed,

the workpiece must be properly positioned and

clamped on the chuck. While the magnetic field

is effective at keeping the workpiece from lifting

off the table during use, it may not be sufficient

to keep the workpiece from sliding. To keep the

workpiece from sliding, use the work stop.

To use work stops:

1. DISCONNECT MACHINE FROM POWER!

2. Turn ON/OFF selector to OFF.

3. Loosen cap screws securing work stops, lift

work stop high enough so it is above surface

of magnetic chuck, but below workpiece sur-

face, as shown in

Figure 4, then re-tighten

cap screws.

4. Position workpiece so it is near center of

chuck, as shown in

Figure 4.

Hex Bolts

Hex Bolts (2 of 4) Stops

Workpiece

Workpiece

Spacer

Turn to

ON Position

Workpiece & Spacers

Snug Against Stops

Work Stop

Figure 4. Positioning work stop and spacer.

Non-striped areas at the ends of the chuck

DO NOT produce a significant magnetic field

and WILL NOT securely clamp workpiece.

Placing a workpiece in these areas could

result in workpiece being ejected from chuck

and thrown into operator or bystanders

during use!

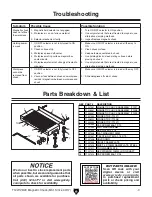

5. Place a spacer strip of steel bar (it must

be thinner than workpiece) as necessary

between workpiece and work stop to provide

bracing against slippage.

Note:

Spacer strip also aids in proper work-

piece alignments to magnetic chuck and

grinder.

6. Make sure workpiece is snug against spacer

strip and spacer is snug against stop, then

turn ON/OFF selector to

ON position, as

shown in

Figure 5, to engage magnet.

Hex Bolts

Hex Bolts (2 of 4) Stops

Workpiece

Workpiece

Spacer

Turn to

ON Position

Workpiece & Spacers

Snug Against Stops

Work Stop

Figure 5. Positioning work stop and spacer.

7. Make sure workpiece is secured by pulling

upward on it with moderate to strong force. If

it releases, turn magnetic chuck

OFF, make

sure mating surfaces are clean, then repeat

Step 6.

— If you are unable to secure workpiece with

magnetic chuck, you will need to use an

alternative mounting method.

Summary of Contents for T1227

Page 8: ......