-30-

Model T10875 (Mfd. Since 01/15)

Operation

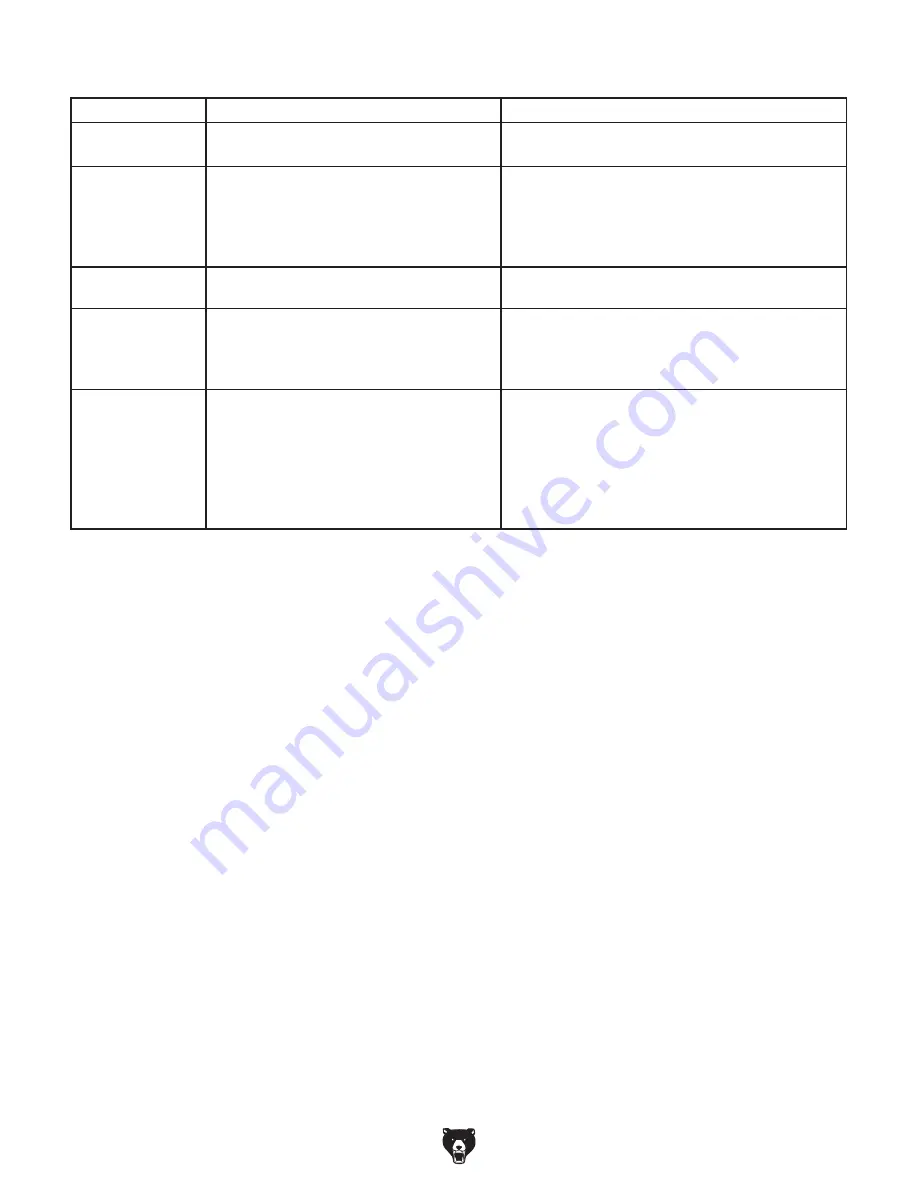

Symptom

Possible Cause

Possible Solution

M

achine slows when

operating.

1. Operator is using too much pressure.

2. RPM too low.

1. Use less pressure when grinding.

2. Adjust RPM.

Wavy condition

on surface of

workpiece.

1. Machine vibrating.

2. Workpiece not being held firmly.

3. Wheel face uneven.

4. Wheel is too hard.

1. Make sure machine is securely mounted on a solid

surface.

2. Use a holding device to firmly retain workpiece.

3. Dress grinding wheel.

4. Use softer wheel, or reduce feed rate.

Lines on surface of

workpiece.

1. Impurity on wheel surface.

2. Workpiece not being held tightly.

1. Dress grinding wheel.

2. Use a holding device to firmly retain workpiece.

Burning spots

or cracks in the

workpiece.

1. Improper type of grinding wheel.

2. Improper feed rate.

3. Workpiece requires quenching.

1. Try a wheel which is softer style or coarser grit.

2. Slow down rate of movement of workpiece into

wheel.

3. Quench workpiece in water to cool.

Wheel dulls quickly,

grit falls off.

1

. Depth of cut too great.

2. Wheel is too soft.

3. Wheel diameter too small.

4. Bad wheel dress.

5. Defective wheel bonding.

1

. Slow down rate of movement of workpiece into

wheel.

2. Wheel too soft for material being ground; select

harder bond.

3. Replace wheel.

4. Dress wheel.

5. Consult manufacturer of grinding wheel.

Summary of Contents for T10875

Page 40: ......