Model G9972Z (Mfd. Since 03/20)

-41-

4. Configure the V-belt on the pulleys according

to the letter and number combination under

the selected spindle speed from the chart in

Figure 48.

Position the idler pulley on top of the V-belt

with enough downward pressure to provide

tension to the belt, then fully secure it in

place. There is correct tension to the V-belt

when there is approximately

1

⁄

2

" deflection

when moderate pressure is applied to the

V-belt half-way between the pulleys.

Note: The pulley slots are numbered 1–3

with number 1 being the outside slot.

— For "A–C" configurations (see

Figure 49),

position the longer V-belt (32" in circum-

ference) in the correct "C" pulley slot, then

roll it onto the "A" pulley.

—For "B–C" configurations (see

Figure 50),

place the shorter V-belt (29" in circumfer-

ence) in the correct "C" pulley slot, then

roll it onto the "B" pulley.

Power Feed

"Power Feed" on a lathe simply means using the

machine-driven components to feed the tool into

the workpiece rather than feeding it manually with

handwheels.

The speed at which the carriage travels is set with

the feed rate dials (see

Feed Rate on Page 42

for detailed instructions), but it also depends on

spindle speed.

NOTICE

Feed rate is based on the spindle speed.

High feed rates result in a rapidly moving

carriage. Pay close attention to the feed

rate you have chosen and keep your hand

poised over the power feed lever. Failure to

fully understand this could cause the car-

riage to crash into the spindle or tailstock

resulting in severe damage to the lathe.

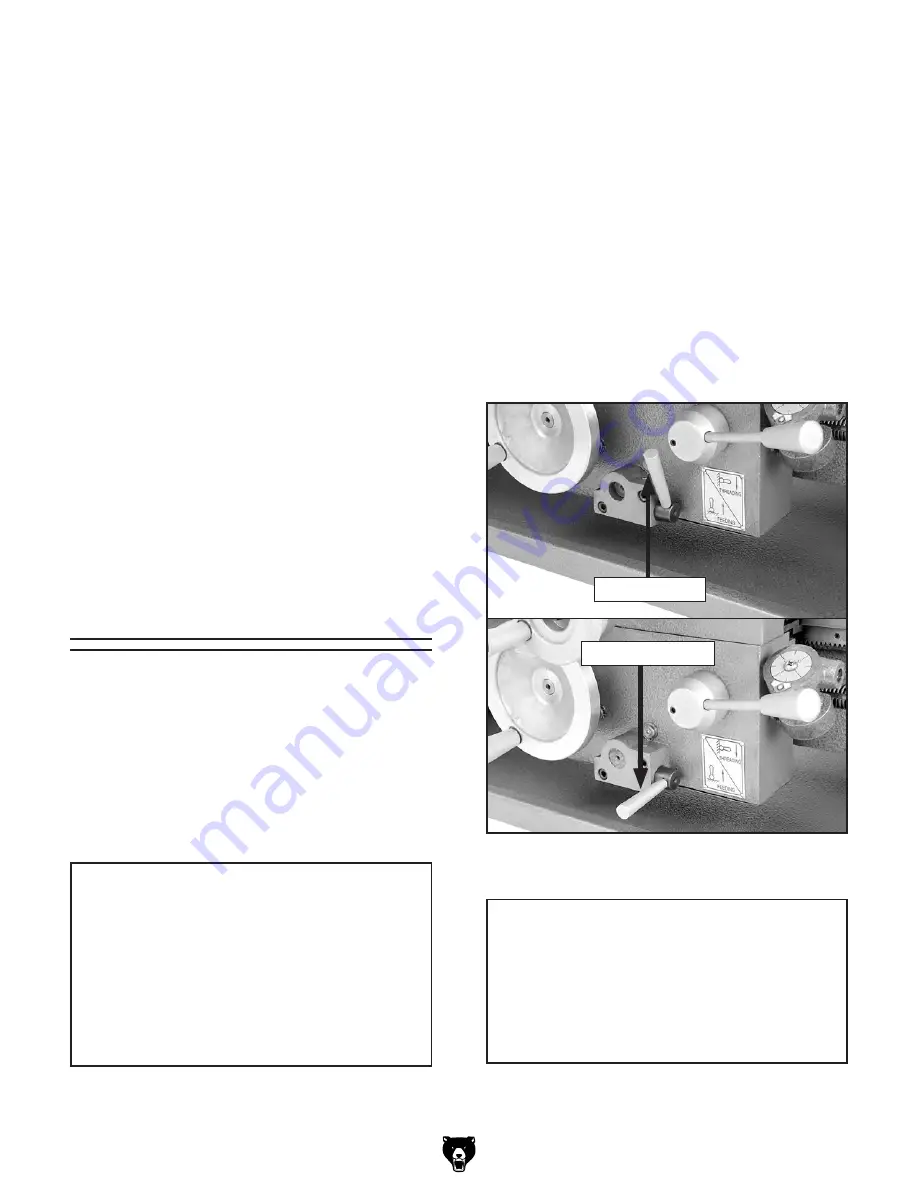

When the proper feed rate has been selected for

the operation, simply move the power feed lever

up to engage the carriage with the power feed

(see

Figure 51). Move the lever down to disen-

gage the power feed.

When the spindle is rotating counterclockwise

(towards the operator), the carriage will move

toward the spindle when engaged with the power

feed. Conversely, when the spindle is rotating

clockwise (away from the operator), the carriage

will move toward the tailstock.

Note: If the spindle is not turning, you may have

to manually jog the carriage to engage the apron

gearing with the leadscrew.

NOTICE

NEVER attempt to engage the carriage

power feed (lever up) and the half-nut (lever

down) at the same time. Always disengage

the half-nut (lever up) before moving the

power feed lever up. Otherwise, severe

damage to the lathe could occur.

Figure 51. Power feed lever engaged and

disengaged.

Disengaged (Off)

Engaged (On)

Summary of Contents for G9972Z

Page 84: ......