G4017–20 (Mfd. 02/15+)

-5-

Wipe the arbor press down with a clean shop rag

and mineral spirits. When dry, protect the unpaint-

ed surfaces by applying a thin film of ISO 32 oil.

Grease ..................T23964 or NLGI#2 Equivalent

Grease Amount ................................. As Needed

Lubrication Frequency .........40 Hrs. of Operation

Tools Needed

Qty

Wrench or Socket 12mm (G4017, G4018) ......... 1

Wrench or Socket 14mm (G4019, G4020) ........ 1

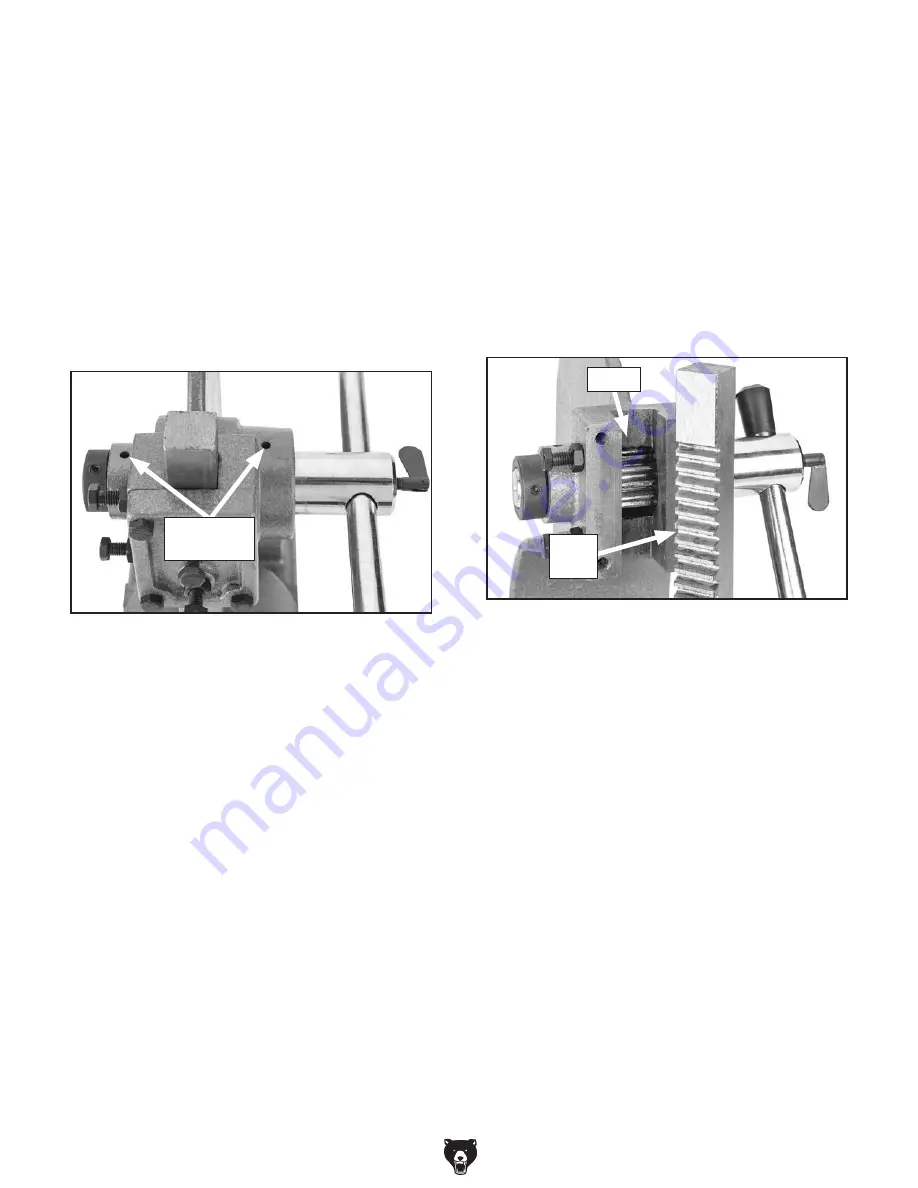

To grease rack and pinion:

1. Remove front plate, then remove ram to

expose pinion and rack (see

Figure 11).

2. Use shop rags, a stiff brush, and mineral spir-

its to clean teeth of rack and pinion.

3. When dry, apply a light coat of grease to rack

and pinion teeth.

4. Re-install ram and front plate.

5. Use sliding handle to move ram up and down

several times to distribute grease.

Figure 11. Ram rack and pinion exposed after

removing front plate.

Pinion

Ram

Rack

Cleaning & Protecting

Oiling Pinion Hub Shaft

Push the tip of the oil can nozzle against the oil

access hole and pump oil can once or twice. If

you see sludge and contaminants coming out

of the lubrication area, continue pumping the oil

can until the oil runs clear. Move the components

through the entire path of travel a few times to

distribute the oil. When finished, wipe away the

excess oil.

Figure 10. Locations of oil access holes to

lubricate pinion hub shaft.

Oil Access

Holes

Oil Type .................T26685 or ISO 32 Equivalent

Oil Amount ......................................... 1–2 Pumps

Lubrication Frequency ...........8 Hrs. of Operation

Proper lubrication of the pinion hub shaft is done

with a pump-type oil can with a cone tip through

the oil access holes (see

Figure 10).

Greasing Rack and Pinion