Model G0925 (Mfd. Since 02/20)

-19-

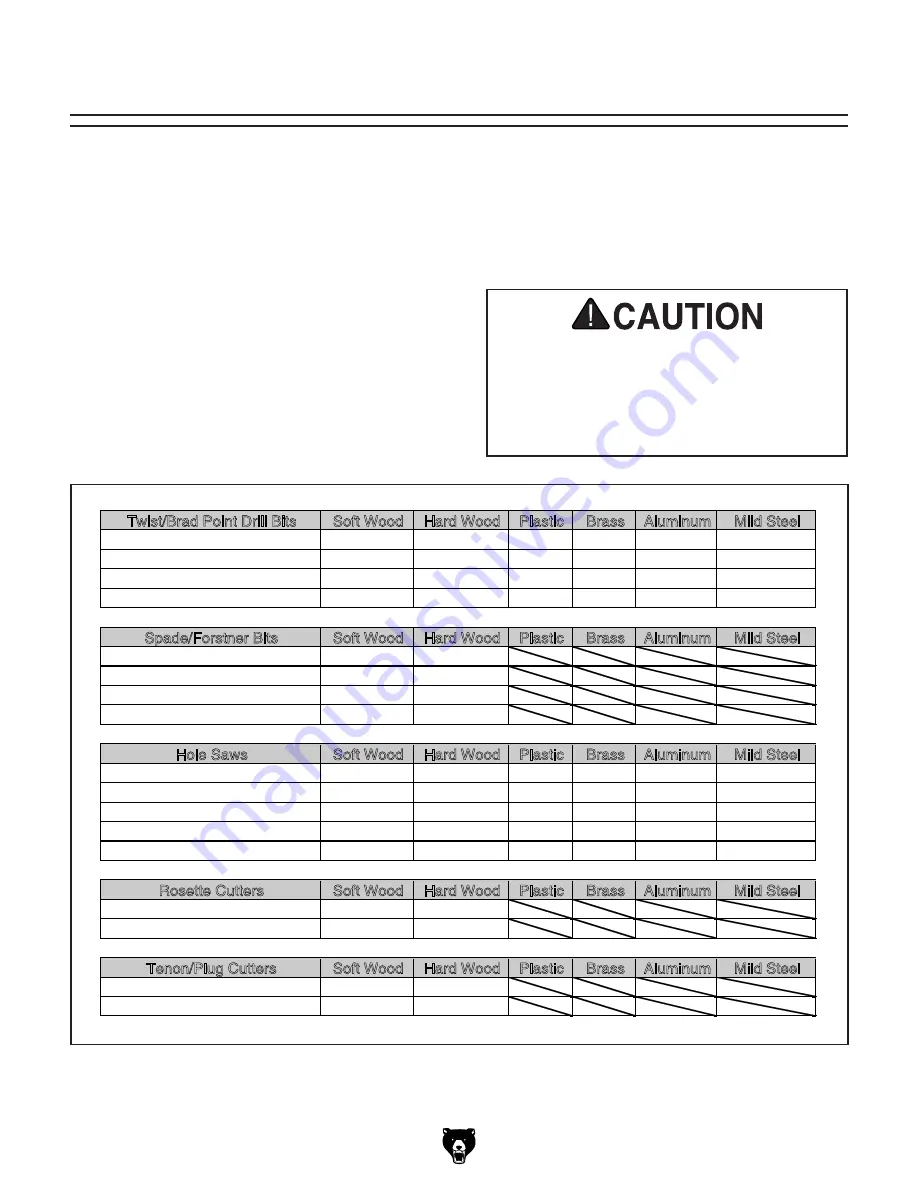

Choosing Spindle Speeds

Twist/Brad Point Drill Bits

Soft Wood

Hard Wood

Plastic

Brass

Aluminum

Mild Steel

1/16" – 3/16"

3000

2500

2500

2500

3000

2500

13/64" – 3/8"

2000

1500

2000

1250

2500

1250

25/64" – 5/8"

1500

750

1500

750

1500

600

11/16" – 1"

750

500

1000

400

1000

350

Spade/Forstner Bits

Soft Wood

Hard Wood

Plastic

Brass

Aluminum

Mild Steel

1/4" – 1/2"

2000

1500

9/16" – 1"

1500

1250

1-1/8" – 1-7/8"

1000

750

2–3"

500

350

Hole Saws

Soft Wood

Hard Wood

Plastic

Brass

Aluminum

Mild Steel

1/2" – 7/8"

500

500

600

600

600

500

1" – 1-7/8"

400

400

500

500

500

400

2" – 2-7/8"

300

300

400

400

400

300

3" – 3-7/8"

200

200

300

300

300

200

4" – 5"

100

100

200

200

200

100

Rosette Cutters

Soft Wood

Hard Wood

Plastic

Brass

Aluminum

Mild Steel

Carbide Insert Type

350

250

One-Piece Type

1800

500

Tenon/Plug Cutters

Soft Wood

Hard Wood

Plastic

Brass

Aluminum

Mild Steel

3/8" – 1/2"

1200

1000

5/8" – 1"

800

600

Using Drill Bit Speed Chart

The chart shown in

Figure 16 is intended as a

generic guide only. Always follow the manufac-

turer's speed recommendations if provided with

your drill bits, cutters, or hole saws. Exceeding

the recommended speeds may be dangerous to

the operator.

The speeds shown here are intended to get you

started. The optimum speed will always depend

on various factors, including tool diameter, drilling

pressure, material hardness, material quality, and

desired finish.

Often, when drilling materials other than wood,

some type of lubrication is necessary.

Lubrication Suggestions

Wood ...........................................................None

Plastics ............................................Soapy Water

Brass ...............................Water-Based Lubricant

Aluminum ..................... Paraffin-Based Lubricant

Mild Steel ............................. Oil-Based Lubricant

Figure 16. Drill bit speed chart (RPMs).

Larger bits turning at slower speeds tend

to grab workpiece aggressively. This can

result in operator's hand being pulled into

bit or workpiece being thrown with great

force. Always clamp workpiece to table to

prevent reduce risk of injury.

Summary of Contents for G0925

Page 44: ......