-34-

Model G0923 (Mfd. Since 05/20)

Review the troubleshooting procedures in this section if a problem develops with your machine. If you need

replacement parts or additional help with a procedure, call our Technical Support.

Note: Please gather the

serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

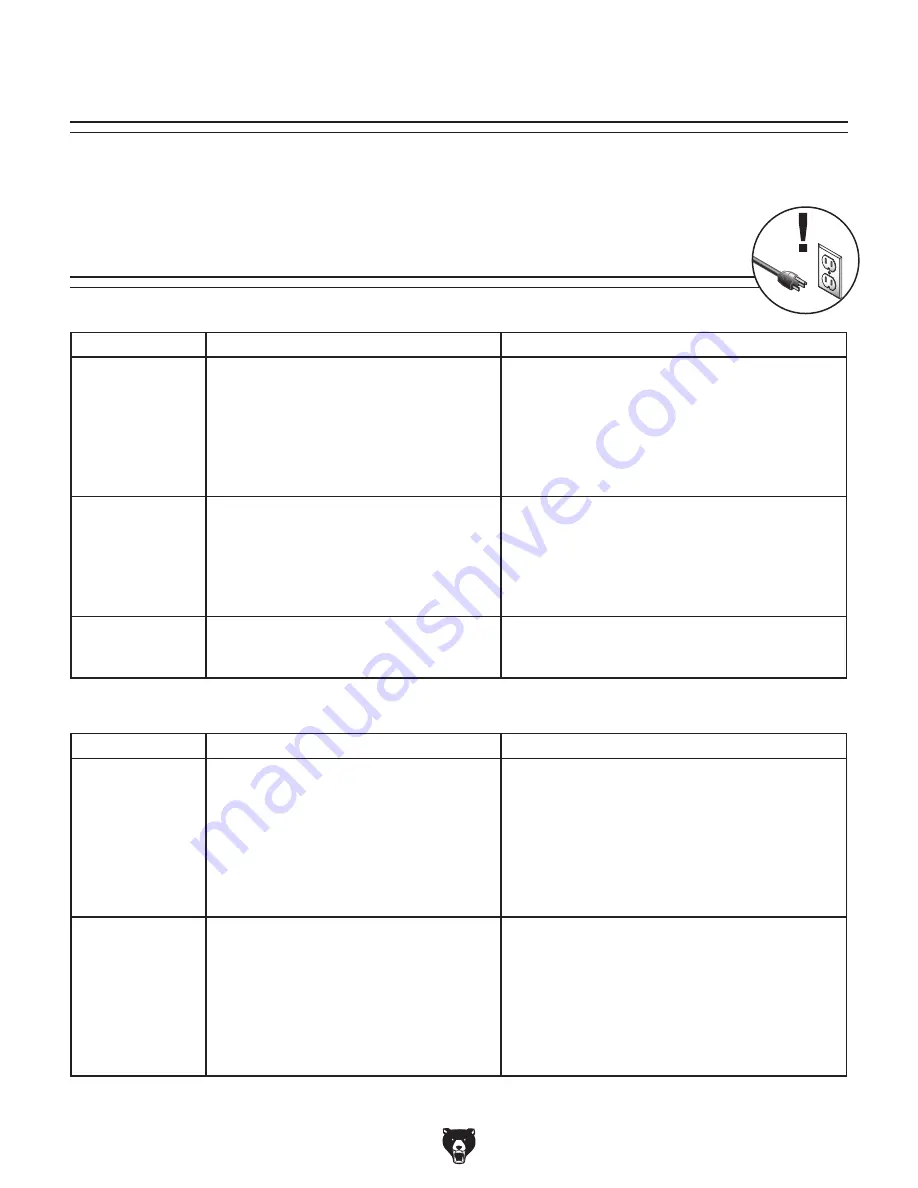

Motor & Electrical

Machine Operation

Symptom

Possible Cause

Possible Solution

Machine does not

start, or power

supply breaker

immediately trips

after startup.

1. Incorrect power supply voltage, circuit size,

or connections.

2. Power supply circuit breaker tripped or fuse

blown.

3. Wiring broken, disconnected, or corroded.

4. Motherboard at fault.

1. Ensure correct power supply voltage, circuit size,

and machine is properly connected.

2. Ensure circuit is sized correctly and free of shorts.

Reset circuit breaker or replace fuse.

3. Fix broken wires or disconnected/corroded

connections.

4. Inspect/replace if at fault.

Machine stalls or is

underpowered.

1. Belts slipping/pulleys misaligned.

2. Motor wired incorrectly.

3. Drive sprockets slipping on shaft.

4. Motor at fault.

5. Motherboard at fault.

1. Tension/replace belt(s); ensure pulleys are aligned

(

Page 44).

2. Wire motor correctly (

Page 46).

3. Tighten/replace loose drive sprockets.

4. Test/repair/replace.

5. Test/repair/replace.

Machine has

vibration or noisy

operation.

1. Cooling fan loose or damage.

2. Motor loose.

3. Motor at fault.

1. Test/repair/replace.

2. Tighten motor to chassis.

3. Test/repair/replace.

Symptom

Possible Cause

Possible Solution

Filament does not

extrude during

printing.

1. Build plate too close to nozzle.

2. Temperature too cool for type of filament.

3. Filament tangled on spool.

4. Nozzle clogged.

5. Heating block at fault.

6. Feed motor at fault.

1. Level build plate (

Page 24).

2. Increase temperature and restart preheating

process (

Page 26).

3. Unwind filament from spool until it is not tangled or

overlapping.

4. Clean (

Page 37) or replace (Page 41) nozzle.

5. Test/repair/replace.

6. Test/repair/replace.

Object does not

stick to build plate.

1. Build plate too far away from nozzle.

2. Insufficient adhesive.

3. Object has small footprint.

4. Incorrect temperature for type of filament.

5. Print speed too fast for type of filament.

1. Level build plate (

Page 24).

2. Clean build plate, then re-apply adhesive (

Page 26).

3. In slicer software, turn on brim, raft, or add

supports.

4. Adjust temperature and restart preheating process

(

Page 26). Lower temperature may require slower

print speed.

5. In slicer software, reduce print speed.

Summary of Contents for G0923

Page 56: ......