-52-

Model G0768/G0769 (Mfd. Since 6/14)

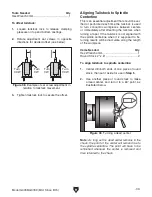

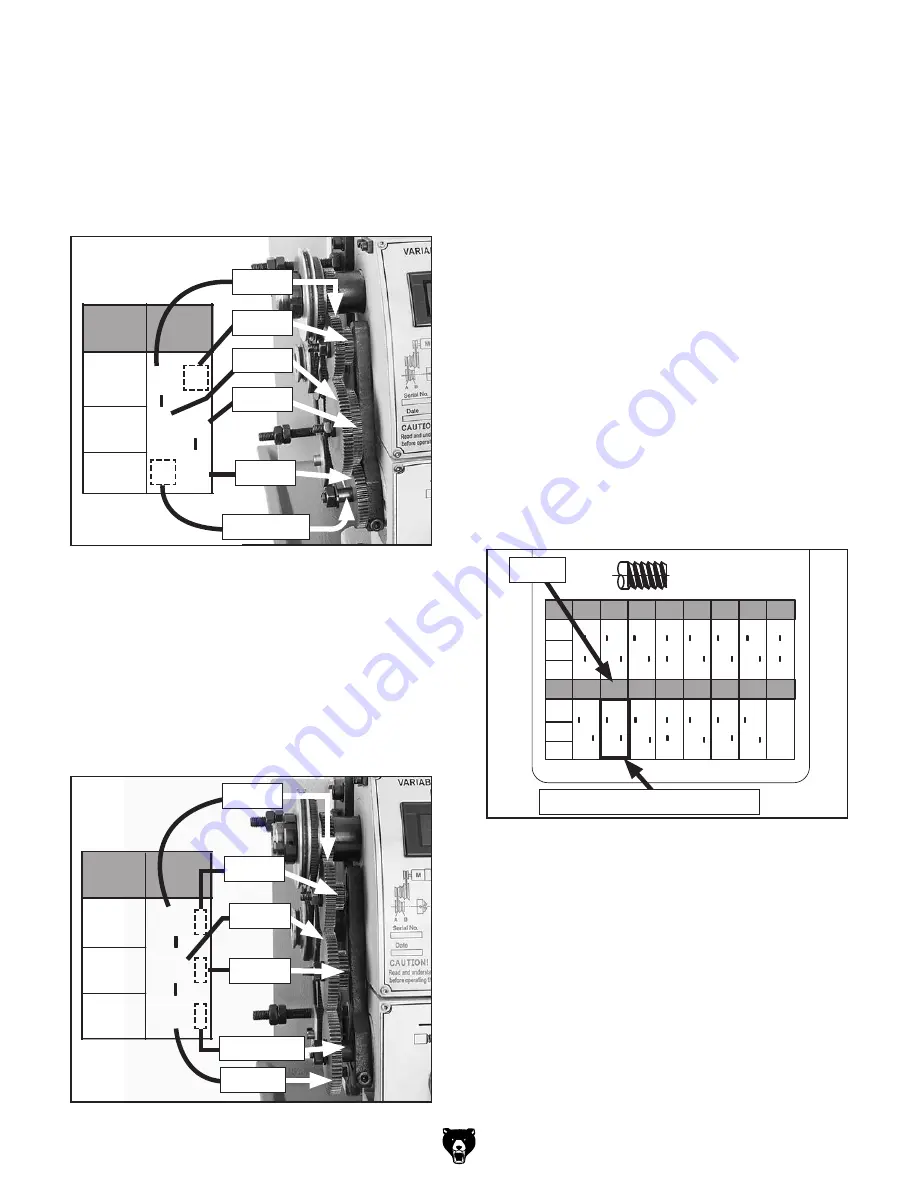

Primary Threading Configuration

This threading configuration is used for inch and

metric threading. Mesh the A and C, and D and F

gears, as shown in

Figure 72. The A/B and C/D

change gears each share a keyed bushing. A

spacer (E) is installed on the lower shaft in front

of the F gear.

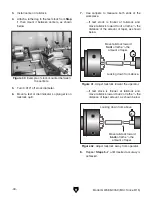

Secondary Threading Configuration

This threading configuration is used for a differ-

ent range of inch threads. Mesh the A, C, and E

gears, as shown in

Figure 73. The A/B, and C/D

gears each share a keyed bushing. The B and D

gears (e.g. 20T or 30T) function as spacers since

they do not mesh with other gears. A spacer (F)

is installed on the lower shaft behind the E gear.

Figure 73. Secondary threading configuration.

A

C D

B

E F

A

C D

B

E F

30

19 20 22 24 32 40 44

80 80

30

33 40

65

70

80 60

60

60

60

63

63

53

9 10 11 12 13 14 16 18

50

50

55

80

80

80

80

80

80 60

60

7153 55

33

30

55

55

4030

53

53

53 72

63

70

57

57 72

72

72

72 80

70 40

40

40

63

57

55

E Gear

A Gear

B Gear

C Gear

D Gear

F (Spacer)

Figure 72. Primary threading configuration.

A

C D

B

E F

A

C D

B

E F

30

19 20 22 24 32 40 44

80 80

30

33 40

65

70

80 60

60

60

60

63

63

53

9 10 11 12 13 14 16 18

50

50

55

80

80

80

80

80

80 60

60

7153 55

33

30

55

55

4030

53

53

53 72

63

70

57

57 72

72

72

72 80

70 40

40

40

63

57

55

A Gear

E (Spacer)

F Gear

B Gear

C Gear

D Gear

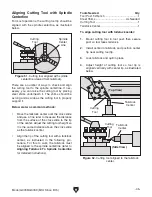

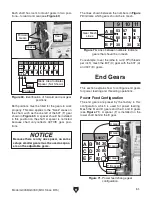

Configuring End Gears

Follow the example below to understand how

to change the gears from the factory set power

feed configuration to the primary inch threading

configuration. Concepts are similar to those for

setting up gears for power feeding.

Note: Many of the techniques and concepts

explained here also apply to setting up gears for

power feeding.

Tools Needed

Qty

Hex Wrench 5mm .........................................1 Ea

Open-End Wrenches 6, 14, 17mm ...............1 Ea

Punch ................................................................ 1

Hammer ............................................................. 1

To configure end gears for 20 TPI:

1. DISCONNECT MACHINE FROM POWER!

2. Locate 20 TPI on thread chart shown in

Figure 74.

3. Gather 53T, 80T, 60T, and 50T gears. (The

80T gear may already be installed.)

4. Remove end gear cover.

Figure 74. Gear positions for 20 TPI on thread

chart.

0.0037"

84

20

A

A

40

in/

mm

n/1"

C

C

D

D

B

B

E

E

F

A

C D

B

E F

A

C D

B

E F

F

80

80

0.40

1.25 1.50 1.75 2.00 2.50 3.00

55

80

80

53

71

7163

57

71

71

63

33 3060 40

40

50

60

84

80

50

60

20

80

80

80

63

63

80

60

70

70

70

57

72

80

80

30

33 53 30 60 40 40

40

30

33

70

0.50 0.60 0.70 0.80 1.00

80

30 72

33 80

30

0.0068"

A

C D

B

E F

A

C D

B

E F

30

19 20 22 24 32 40 44

80 80

30

33 40

65

70

80 60

60

60

60

63

63

53

9 10 11 12 13 14 16 18

50

50

55

80

80

80

80

80

8060

60

7153 55

33

30

55

55

4030

53

53

53 72

63

70

57

57 72

72

72

72 80

70 40

40

40

63

57

55

20 TPI

Gears and Positions Needed