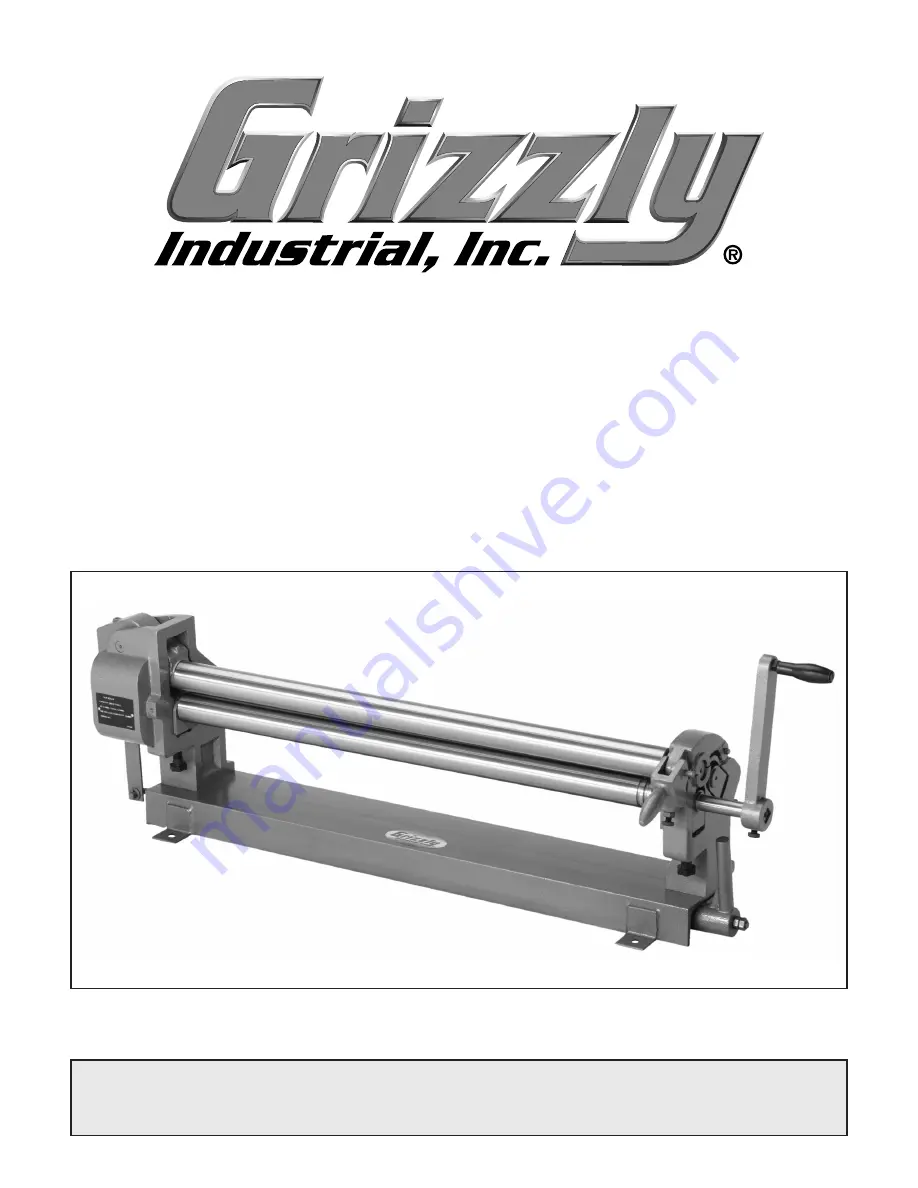

MODEL G5770

36" SLIP ROLL 22 GAUGE

OWNER'S MANUAL

Copyright © May, 2008 By grizzly industrial, inC.

WARNING: NO PORtION Of thIS MANUAL MAy bE REPRODUcED IN ANy ShAPE

OR fORM WIthOUt thE WRIttEN APPROvAL Of GRIzzLy INDUStRIAL, INc.

#JB10753 printed in China