GMAC Installation Guide

Rev 1.0

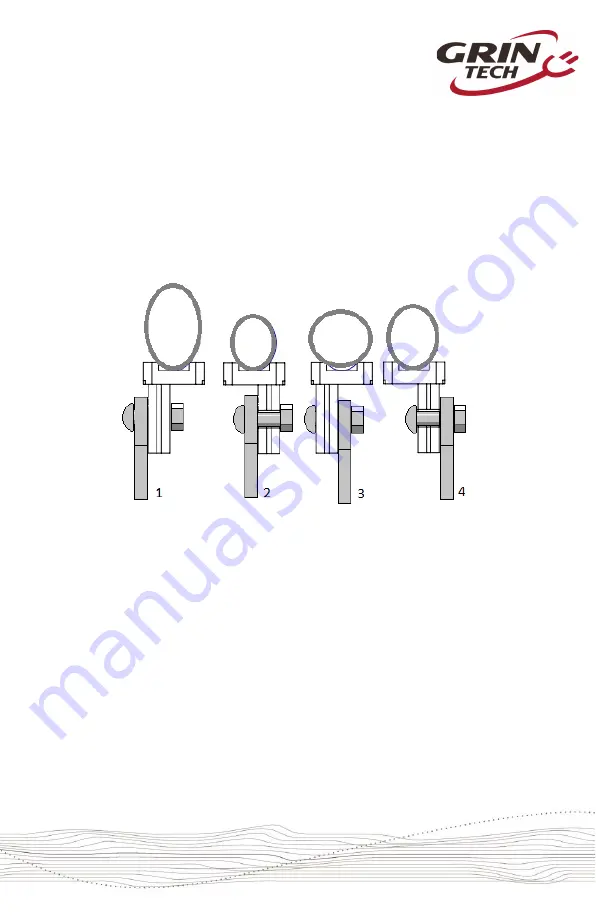

The final stage is to align the Frame Holder for the best fit to the torque arm. The

holder is made deliberately asymmetric so that it can be flipped 180 degrees in

order to accommodate a wide range of frame geometries with 4 different

alignment planes. Select the one that fits most closely with the plane of the

torque arm, and then secure them together with the M5 bolt and flanged nyloc

nut.

Finally, secure the Frame Holder to the chainstay using the two hose-clamps. The

black shrink tubing can be installed over each band in order protect the paint

finish and have a more discrete look.

The M10 washers and axle nuts must also be installed and thoroughly tightened

on the GMAC motor axle. We recommend tightening to at least 40 Nm (30 ft-lb).