HG3555A/42306 Portable Power Unit

Greenlee Textron / Subsidiary of Textron Inc.

12

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

Maintenance (cont’d)

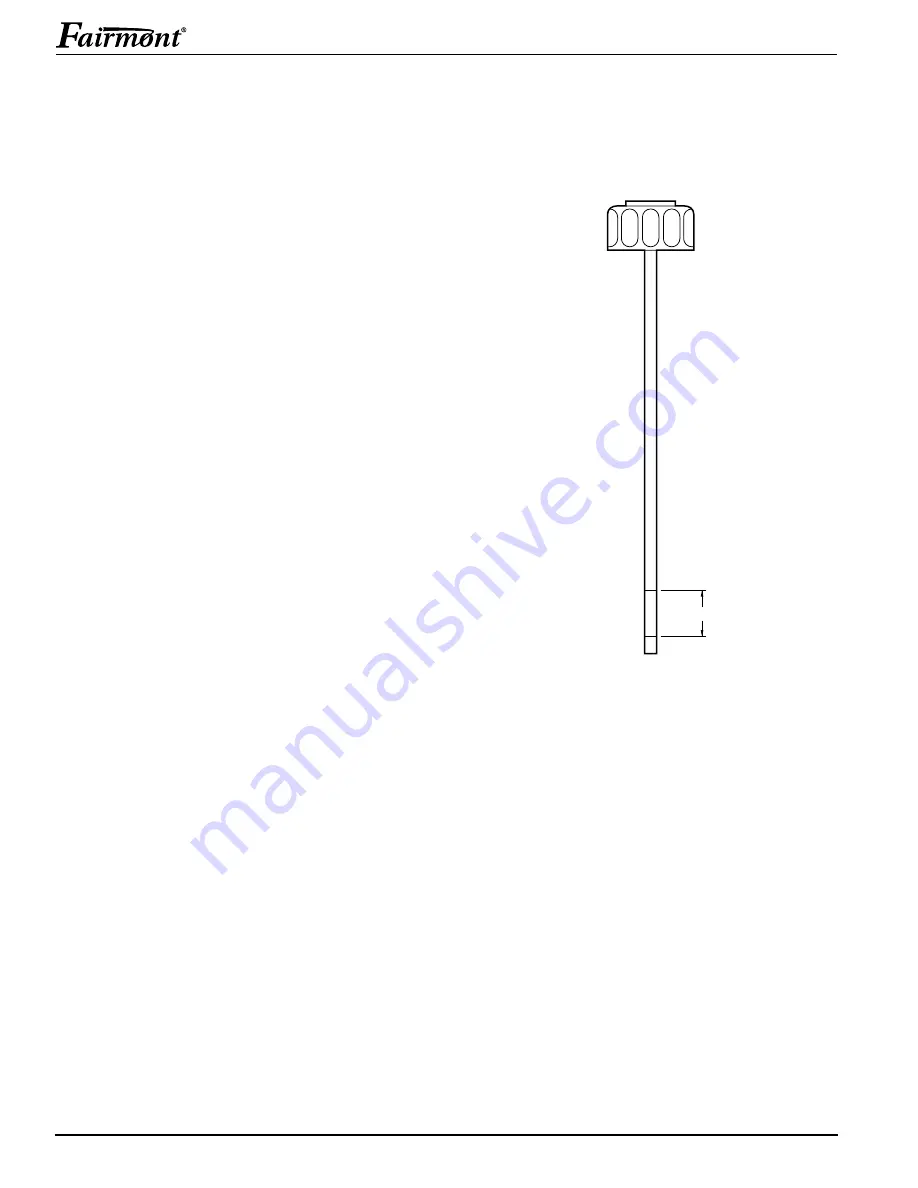

Figure 5

Hydraulic Reservoir Dipstick

F

E

OPERATING AREA

The service life of the power unit will be maximized by

proper care and maintenance. The maintenance sched-

ule below is recommended.

Note: Change engine oil after the first 5 hours of

operation. Thereafter, change engine oil

according to the Maintenance Schedule.

Every 5 Hours

1.

Check engine crankcase oil level. Fill if necessary.

See Oil Recommendations – Engine Manual.

2.

Check fuel tank level. Fill if necessary. See Fuel

Recommendation – Engine Manual.

3.

See Figure 5. Check hydraulic reservoir oil level. Fill

to FULL mark on dipstick. Do not overfill reservoir.

See Recommended Hydraulic Fluids.

Every 10 Hours

1.

Wipe all power unit surfaces clean of grease, dirt

and foreign material.

2.

Inspect the hydraulic system hoses and fittings for

signs of leaks, cracks, wear, or damage. Replace if

necessary.

Every 25 Hours

1.

Service engine air cleaner pre-cleaner. See Engine

Manual.

Every 50 Hours

1.

Change engine crankcase oil and oil filter. See

Engine Manual.

Every 100 Hours or Once Yearly

1.

Drain hydraulic reservoir oil. Clean and flush reser-

voir. Change hydraulic oil filter. Fill reservoir with

new, clean hydraulic oil. See Recommended Hy-

draulic Fluids. Operate power unit to circulate oil

through the hydraulic system. Stop power unit.

Recheck hydraulic oil level. Fill reservoir to the

FULL mark on the dipstick. Do not overfill reservoir.

See Figure 5.

2.

Service engine air cleaner cartridge. See Engine

Manual.

3.

Perform a detailed inspection of the system hoses

and fittings as stated in Appendix A – S.A.E Stan-

dard J1273, May 1986. Replace the hoses and/or

fittings if necessary.