tape or heat shrink material. Tie the string to the aileron

servo extension and pull the wire out of the hole on top of

the bottom wing halves with the string. Tape the connector

to the wing to prevent it from falling back inside the wing.

Then discard the string. The end of the aileron extension in

the top wing halves should be taped to the wing halves until

it is time to join them with the center section of the wing.

This is covered in detail later in this manual.

❏ ❏ ❏ ❏

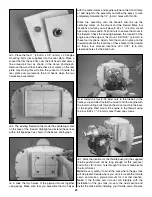

10. Insert the grommets and brass eyelets into the

servo as shown. These are included with the hardware

package for the servos. Place the servo into its opening in the

wing half and drill 1/16" (1.6mm) holes in the wing for the

servo

mounting screws

(also included in the hardware package).

Use the techique shown on page 8 to harden the threads.

Mount the aileron servos using the servo mounting screws.

❏ ❏ ❏ ❏

11. The

servo arms

for the aileron servos are

installed so that they point outboard toward the wing tips as

shown in the above photograph. This is necessary for

proper function.

❏ ❏ ❏ ❏

12. Use a builder's triangle to establish a line to

the hole in the servo arm at 90 degrees from the trailing

edge of the wing. At this location use a nylon control horn

as a pattern to mark and drill the four 5/64" (2 mm) holes

1/2" (13 mm) deep into the bottom of each aileron for

mounting the nylon control horns. As shown on page 8, run

the #4 sheet metal screws into the wood. Then remove

them, creating threads in the wood. Saturate these holes

with thin CA, wipe away any residual CA and allow it to fully

harden. Mount the aileron control horns to the ailerons with

four #4 x 1/2" (13mm) sheet metal screws.

❏ ❏ ❏ ❏

13. Install a

metal clevis

, a 4-40

hex nut

, and a

clevis retainer

on the 4-40 x 12" (305mm)

threaded one

end pushrod

approximately 15 turns. Remember to use

Great Planes Pro Threadlocker (GPMR6060)

on these

clevises and hex nuts after the radio is set up and control

throws have been finished later on in this manual.

10