YP3025A

Troubleshooting

95

2019-06-12

401-705M

Row-unit

discs not

turning freely

Row-unit plugged with dirt.

Clean row-unit.

Planting conditions too wet.

Wait until drier weather.

Incorrect side depth wheel adjustment

Seed-Lok

®

is plugging row-unit.

Lock up Seed-Lok

®

Failed disc bearings.

Replace disc bearings.

Bent or twisted row-unit frame.

Replace row-unit frame.

Partially plugged row-unit seed tube.

Lift up Planter, expose bottom of seed tube and clean out.

Press wheels

not

compacting

the soil as

desired.

Incorrect spring handle setting

Insufficient row unit down-force

Use of incorrectly shaped tire for your

conditions.

Wedge shaped wheels work best on narrow spacings and in wet

conditions. Round edge wheels work best in wider row spacings

and drier conditions.

Not level front to rear.

Check tongue height.

Wheel stagger needs adjustment for

conditions

Too wet or cloddy

Wait until drier weather or rework ground.

Seed blowing

out of bulk

box door

area

Fan too fast.

Slow down fan.

Seal from airbox to hopper damaged or

not adjusted.

Inspect and adjust seal. Seal should be intact, and compress to

about

3

/

8

inch (13 mm) under seed container.

Air lines

plugging

between air

box and Y

tubes

Fan too slow.

Speed up fan.

Air leaks between air box manifold and

splitters

Check for leaks and correct as needed.

Improper hose routing, sags or kinks

With Planter unfolded, hoses should for a gentle “S” shape through

the holders, with no deep sags.

Air lines

plugging

between

Y-tube and

meter

Sag or kink in air hose.

Check air tube placement in tube mount weldment. If correct,

shorten any hose that has stretched due to age.

Meter is shut off but Y-tube is open.

Shut off Y-tube.

Air tube assembly not positioned on

correct tab.

Move assembly to properly position Y-tubes over row meters.

Sag in air hose due to incorrect frame

height

Raise or lower the tongue so center portion of frame is level with

gauge wheel area.

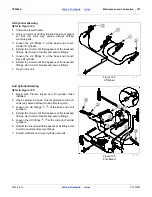

Hydraulic

marker

functioning

improperly,

or not at all

Marker/Fold switch set to Fold.

CFM Switch must be set to “Marker”. Set tractor remote circuit to

Neutral or Float before operating switch.

Marker/Aux valve set to Aux

On a Planter with optional Auxiliary Hydraulics, selector valve must

be set to Marker for markers to function. Set tractor remote circuit to

Neutral or Float before changing valve.

Air or oil leaks in hose fittings or

connections.

Check all hose fittings and connections for air or oil leaks.

Low tractor hydraulic oil level.

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners.

Check all bolts and fasteners.

Needle valve(s) in sequence valve

plugged.

Open needle valves, cycle markers slowly and reset needle valves,

refer to page 172.

General Troubleshooting

Problem

Cause

Solution