440 04 7113 02

13

Specifications subject to change without notice.

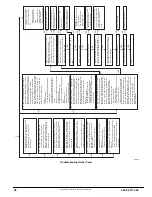

Table 5 – Air Delivery -- CFM (With Filter)

SIZE

RETURN AIR

CONNECTION

WIRE

LEAD

COLOR

COOLING

TONS

CFM

/TON

TEST AIRFLOW DELIVERY @ VARIOUS EXTERNAL STATIC PRESSURES

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

040A030C

SIDE/BOTTOM

Black

2.5

388

1145

1100

1060

1015

970

920

860

785

680

615

Blue

2.0

413

970

940

905

870

825

775

730

675

570

505

Yellow

2.0

385

910

880

845

810

770

725

675

600

535

475

Red

1.5

397

725

695

665

635

595

555

510

460

390

340

060B048C

SIDE/BOTTOM

Black

4.0

376

1600

1545

1505

1475

1505

1445

1400

1330

1235

1140

Yellow

3.5

377

1380

1340

1335

1330

1320

1285

1225

1155

1085

1000

Blue

3

3.0

387

1190

1185

1195

1195

1160

1125

1075

1015

950

885

Red

3

2.5

394

1030

1025

1030

1010

985

940

905

855

805

735

080B048B

(B Series

Only)

SIDE/BOTTOM

Black

4.0

408

1800

1770

1735

1685

1630

1570

1495

1415

1330

1230

Yellow

3.5

386

1445

1430

1410

1385

1350

1305

1255

1195

1120

1045

Orange

3.0

390

1250

1240

1225

1200

1170

1130

1090

1040

975

910

Blue

2.5

404

1090

1080

1060

1035

1010

970

930

885

835

765

Red

3

2.0

390

880

860

835

810

780

750

710

665

615

560

080B048C

(C Series

Only)

SIDE/BOTTOM

Black

4.0

389

1650

1620

1640

1605

1555

1495

1425

1345

1255

1165

Yellow

3.5

381

1420

1425

1400

1370

1335

1290

1230

1170

1095

1015

Orange

3.0

383

1205

1205

1185

1165

1150

1100

1055

1000

935

870

Blue

2.5

384

1035

1020

1005

985

960

930

895

845

795

735

Red

3

2.0

380

850

825

805

785

760

725

695

655

600

545

080C060C

BOTTOM or

TWO--SIDES

4,5

Black

5.0

377

2225

2160

2070

1980

1885

1790

1690

1575

1460

1345

Yellow

4.0

386

1690

1665

1640

1595

1545

1485

1410

1330

1235

1135

Orange

3.5

397

1485

1470

1455

1430

1390

1340

1280

1205

1120

1035

Blue

3

2.5

426

1120

1110

1100

1090

1065

1035

990

935

870

805

Red 3

2.0

433

940

920

910

890

865

830

790

745

690

625

100C048C

SIDE/BOTTOM

Black

4.0

373

1715

1660

1610

1555

1490

1420

1340

1245

1150

1065

Yellow

3

3.5

379

1535

1480

1435

1380

1325

1260

1180

1095

1010

910

Blue

3

3.0

367

1300

1255

1205

1160

1100

1035

970

905

810

730

Red

3

2.0

445

1110

1055

1005

955

890

835

770

690

610

535

100C060C

BOTTOM or

TWO--SIDES

4,5

Black

5.0

394

2270

2205

2130

2055

1970

1880

1780

1670

1555

1425

Yellow

5.0

367

2090

2040

1980

1910

1835

1755

1670

1570

1460

1340

Blue

4.0

416

1850

1815

1775

1725

1665

1600

1525

1435

1335

1225

Red

3.5

421

1580

1550

1540

1515

1475

1420

1355

1280

1190

1100

120D060C

BOTTOM or

TWO--SIDES

4,5

Black

5.0

410

2385

2310

2230

2150

2050

1920

1780

1650

1540

1415

Yellow

5.0

369

2130

2070

2010

1940

1845

1740

1630

1525

1420

1305

Blue

4.0

416

1875

1840

1795

1735

1665

1580

1495

1410

1310

1205

Red

3

3.5

414

1610

1585

1555

1515

1450

1395

1325

1250

1160

1080

NOTES:

1. A filter is required for each return--air inlet. Airflow performance includes a 3/4 in. (19 mm) washable filter media such as contained in

factory--authorized accessory filter rack. See accessory list. To determine airflow performance without this filter, assume an additional

0.1 in. W.C. available external static pressure.

2. ADJUST THE BLOWER SPEED TAPS AS NECESSARY FOR THE PROPER AIR TEMPERATURE RISE FOR EACH INSTALLATION.

3. Shaded areas indicate that this airflow range is BELOW THE RANGE ALLOWED FOR HEATING OPERATION. THESE AIRFLOW

RANGES MAY ONLY BE USED FOR COOLING.

4. Airflows over 1800 CFM require bottom return, two--side return, or bottom and side return. A minimum filter size of 20” x 25” is required.

5. For upflow applications, air entering from one side into both the side of the furnace and a return air base counts as a side and bottom return.

6. All airflows that are shown in BOLD exceed 0.58 Watts per CFM at the given external static pressure.