308936 23

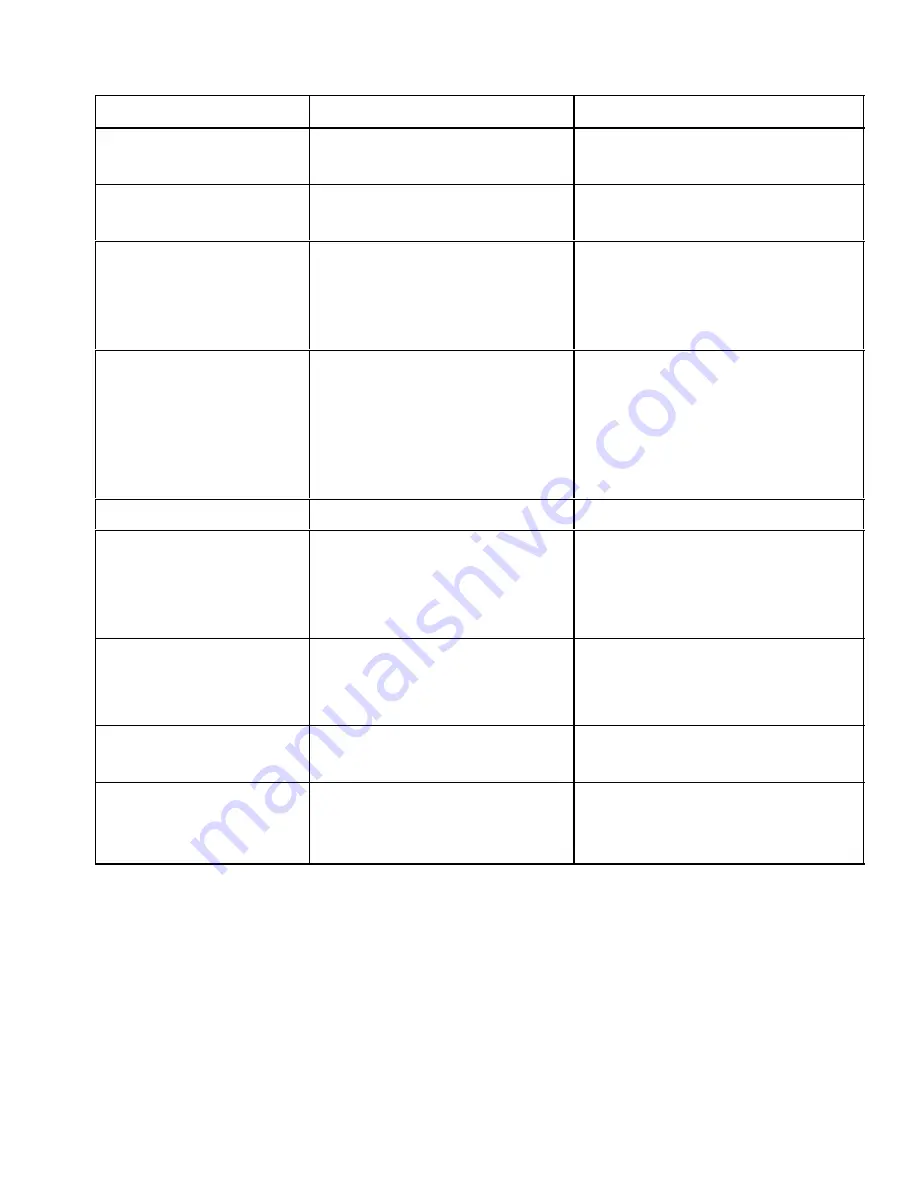

Gun Operation Troubleshooting

PROBLEM

CAUSE

SOLUTION

Leakage from fluid needle area

Fluid needle packings loose

Fluid needle packing damaged

Tighten packing nut; See page 33

Replace fluid needle; See page 34

Air leakage from front of gun

Air valve not turned off

Piston air valve not seating properly

Turn off air (43). See page 15

Clean, Service; See page 39

Fluid leakage from front of gun

Fluid needle worn

Fluid seat loose or worn

Spray tip loose

Tip seal damaged

Replace fluid needle; See page 34

Tighten or replace fluid seat

Tighten retaining nut

Replace tip seal; See page 29

“Orange Peel” finish

CO

2

percentage is too low

Fluid pressure too low

Spray tip or pre-orifice too large

Fluid poorly mixed or filtered

Improper thinner being used

Increase CO

2

percentage

Increase fluid pressure with gun fluid regulator*

Use a smaller size spray tip or pre-orifice;

See page 47

Remix or refilter fluid

Use proper thinner

Excessive spray fog

Fluid thinned too much

Properly thin fluid

No fluid sprays from gun

Fluid supply low

Spray tip or pre-orifice is dirty or clogged

Spray tip damaged

Fluid needle damaged

Check; Add fluid if necessary

Clean spray tip and pre-orifice; See page 20

Check; Replace spray tip; See page 29

Replace fluid needle; See page 34

Equipment covered with fluid

Booth exhaust air flow too low or not

directed properly

Improper distance between gun and

workpiece

Check for proper CFM; Check baffles and

direction of air flow

Adjust spraying distance to 8 to 12 inches

(203 to 305 mm)

Paint build-up on air cap

CO

2

percentage too high

Air cap dirty

Reduce CO

2

percentage

Clean air cap; See page 20

Fluid doesn’t shut off properly

Seat housing over-tightened

Fluid leakage buildup on fluid needle

Fluid packings too tight

Replace seat housing; See page 29

Replace fluid needle; See page 34

Adjust fluid packings; See page 34

* Use the least fluid pressure needed for good results.

Summary of Contents for UNICARB

Page 40: ...40 308936 Notes ...