Operation

10

308345T

kit, to help prevent thick sediment from being forced into

the siphon inlet.

NOTE: If you install an air shutoff valve, the same

agitator speed is set each time it is turned on without

requiring repeated needle valve adjustments.

You can also use an air line quick-disconnect (F) as a

shutoff. See F

. 6. See Air Line Quick-Disconnect,

F

IG

. 7: Operate the Agitator

Shutdown Procedure

1.

To stop the agitator, close the needle valve (18), or

disconnect the quick-disconnect (F), or close the air

valve in the air supply line.

2.

Follow the Pressure Relief Procedure, page 9.

3.

If you remove the agitator from the drum, remove

the bearing nut (8), and hang or tilt the agitator

upright over a container to allow it to drain. Order

part number 189658, accessory handle, so you can

connect a lift hook to raise and lower the agitator or

hang the agitator to store it.

Do not let fluid dry in the fluid tubes. See Clean the

Fluid Tubes, page 12.

NOTICE

Do not operate the agitator at a high speed for a long

period of time. Excessive agitator speed can cause the

fluid to foam and can cause vibration and increased

wear on parts and damage to the drum bung. Only

agitate the fluid fast enough to maintain even mixing.

You can view fluid movement through the 0.75-in. port

on the drum cover.

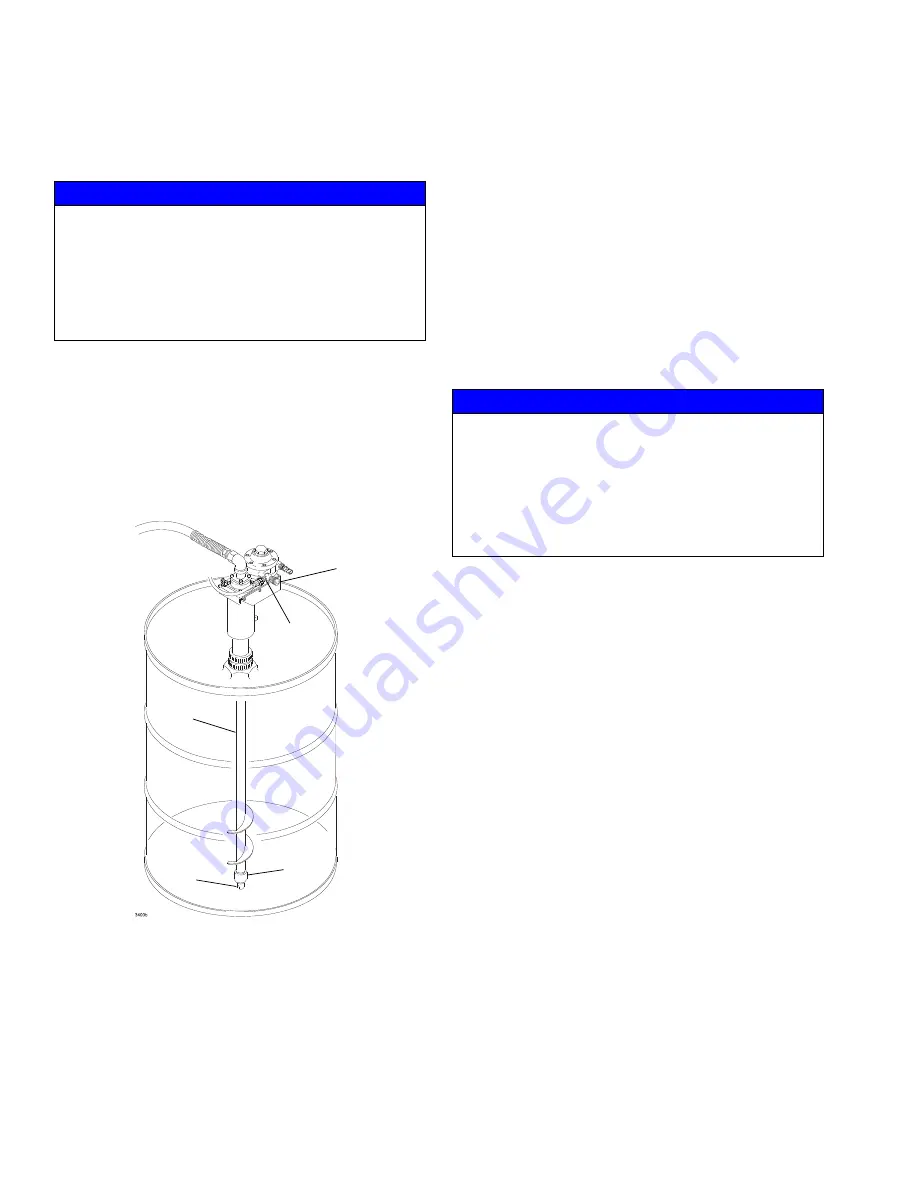

Model 236629 shown

18

F

7

8

4

NOTICE

Keep the agitator upright. Do not lay it on its side or

upside down, because fluid might flow into the beltdrive

area causing damage.

If you use the accessory agitator handle, make sure the

agitator is loosened from the drum before you raise it

with a lift. The handle will not support the weight of the

drum.