Spraying

Spraying

Spraying

The Fusion AP gun is shown.

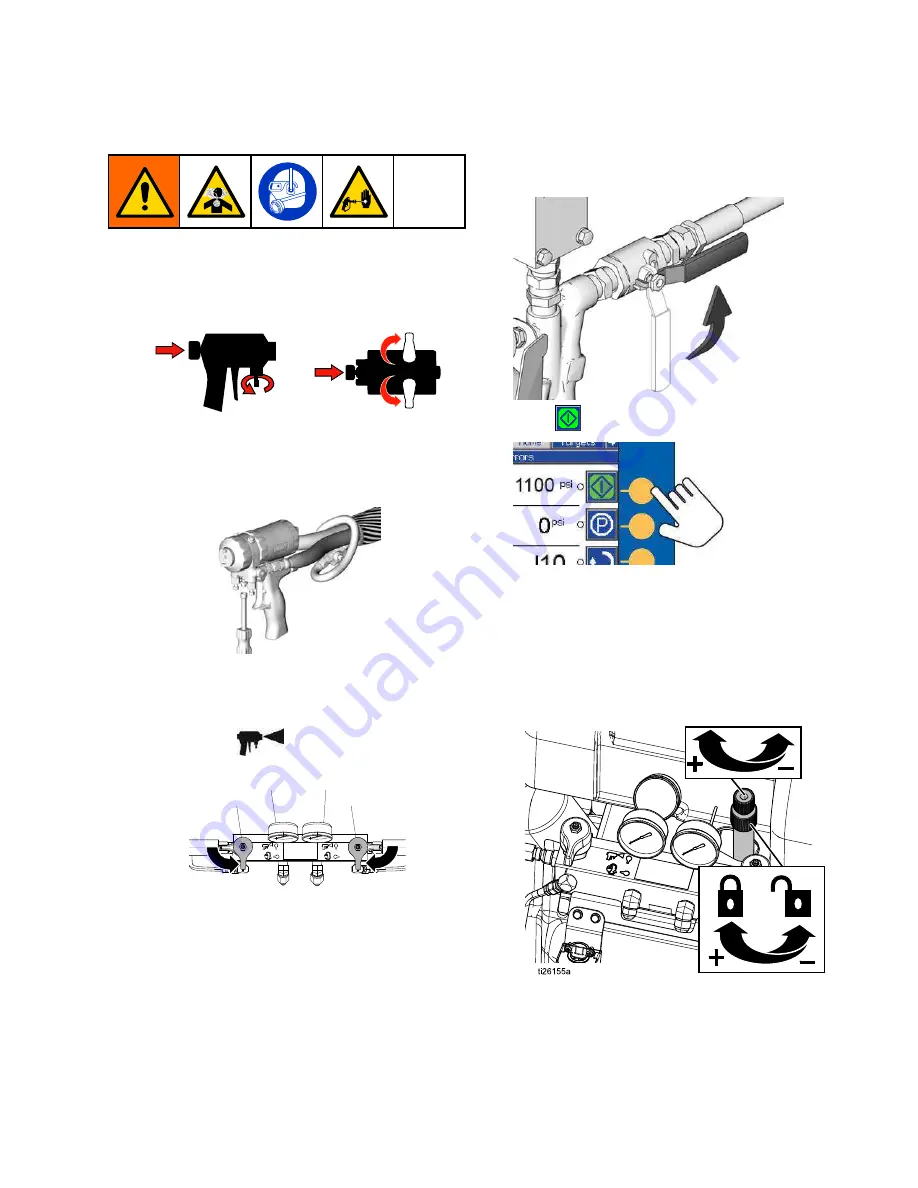

1. Engage gun piston safety lock and close gun

luid inlet valves A and B.

Fusion

Fusion

Fusion

Probler

Probler

Probler

2. Attach gun luid manifold. Connect gun air line.

Open air line valve.

3. Adjust the gun air pressure. Do not exceed 130

psi (0.2 MPa, 2 bar).

4. Set PRESSURE RELIEF/SPRAY valves (SA,

SB) to SPRAY

.

SB

SA

GA

GB

5. Verify heat zones are on and temperatures are

on target, see

6. Open luid inlet valve (FV) located at each pump

inlet.

7. Press

to start motor and pumps.

8. Adjust pressure compensator knob to desired

luid stall pressure. Turn knob clockwise to

increase pressure and counter-clockwise to

decrease pressure. Use hydraulic pressure

gauge (HPG) to view hydraulic pressure. Once

desired luid stall pressure is set, lock the knob

in place by rotating lower portion clockwise until

tight.

Component A and B outlet pressures will be

higher than the hydraulic set pressure, depending

on the model. Component A and B (GA, GB)

pressure may be viewed on the pressure gauges

or the ADM.

334945C

49