Installation

10

309297K

Install the Air Line

Accessories

1.

Install a bleed-type air valve (L) on the main air line

(W) to shut off all air to the gun (H).

2.

Install an air line filter/water separator on the gun air

line to ensure a dry, clean air supply to the gun. Dirt

and moisture can ruin the appearance of your fin-

ished workpiece and can cause the gun to malfunc-

tion.

3.

Install a bleed-type air regulator (M) on each of the

air supply lines (B, C, D, E, X, Y) to control air pres-

sure to the gun.

4.

Install a solenoid valve (K) on the cylinder air line (E)

to actuate the gun. The solenoid valve must have a

quick exhaust port.

Install the Fluid Line

Accessories

1.

Install a fluid filter and drain valve at the pump out-

let.

2.

Install a fluid regulator on the fluid line to control

fluid pressure to the gun.

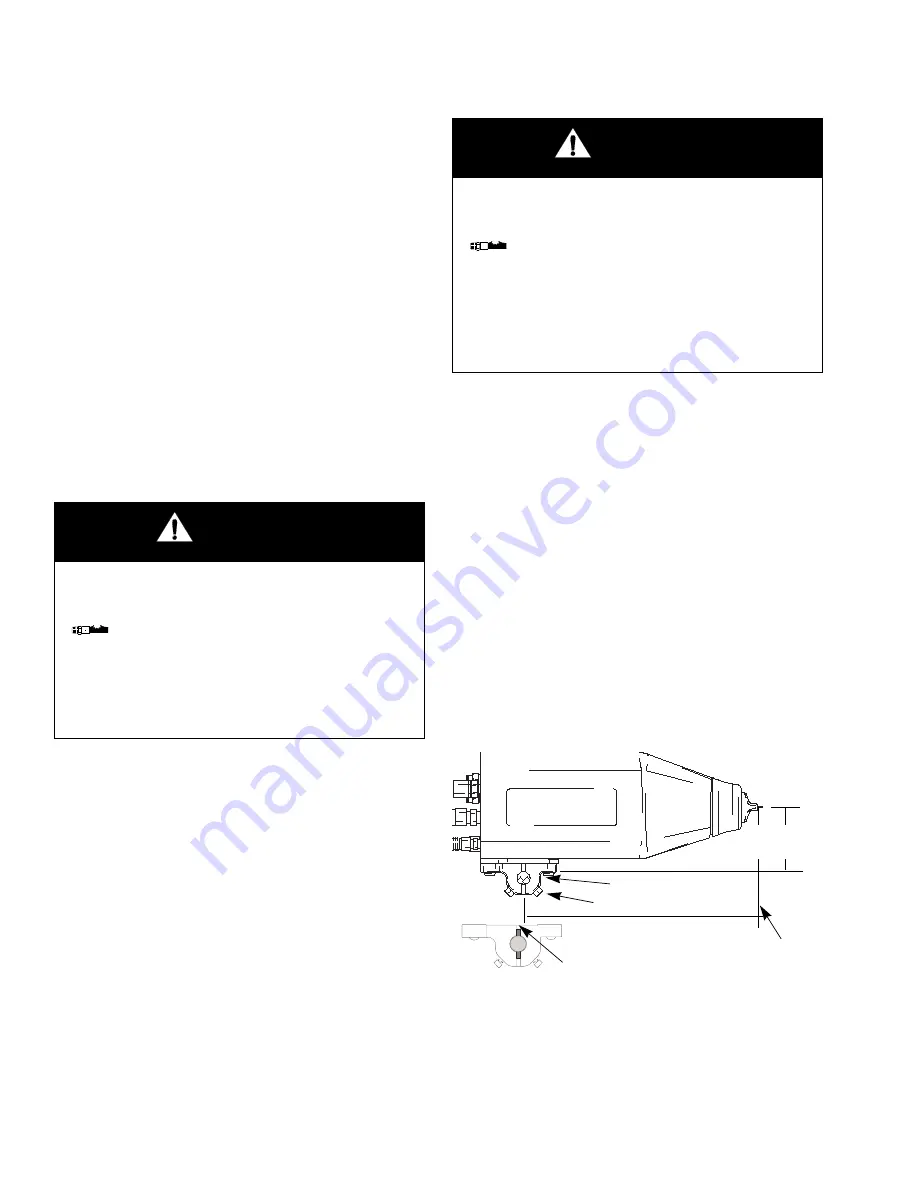

Install the Gun and Mounting

Bracket

1.

Loosen the mounting bracket’s two set screws (103)

and slide the bracket (102) onto a 1/2 in. (13 mm)

mounting rod. See F

2.

Position the gun and tighten the two set screws.

For added positioning reliability, insert a 1/8 in. (3 mm)

locating pin into the slot (NN) in the bracket and through

a hole in the rod. See the detail in F

Fig. 4: Mounting Bracket

WARNING

Pressurized Equipment Hazard

Trapped air can cause the gun to spray

unexpectedly, which can result in serious

injury, including splashing fluid in the eyes

or on the skin. The solenoid valves (K) must

have a quick exhaust port so trapped air will

be relieved between the valve and gun

when the solenoids are shut off.

WARNING

Pressurized Equipment Hazard

The fluid drain valve is required in your sys-

tem to assist in relieving fluid pressure in

the displacement pump, hose, and gun.

Triggering the gun to relieve pressure may

not be sufficient. Install a drain valve close

to the pump's fluid outlet. The drain valve

reduces the risk of serious injury, including

splashing in the eyes or on the skin.

TI1570A

103

102

NN

03460

9.22 in

(234.2 mm)

2.88 in

(73.2 mm)

To nozzle tip

Summary of Contents for PRO Auto Xs Series

Page 44: ...Repair 44 309297K Notes ...