Installation

312877S

9

Mounting

1. For wall mounting, order Graco Kit 24C637.

2. Be sure the mounting surface can support

the weight of the pump, hoses, and acces-

sories, as well as the stress caused during

operation.

3. For all mountings, be sure the pump is

bolted directly to the mounting surface.

4. For ease of operation and service, mount

the pump so air valve, air inlet, fluid inlet

and fluid outlet ports are easily accessible.

5. Rubber Foot Mounting Kit 236452 is avail-

able to reduce noise and vibration during

operation.

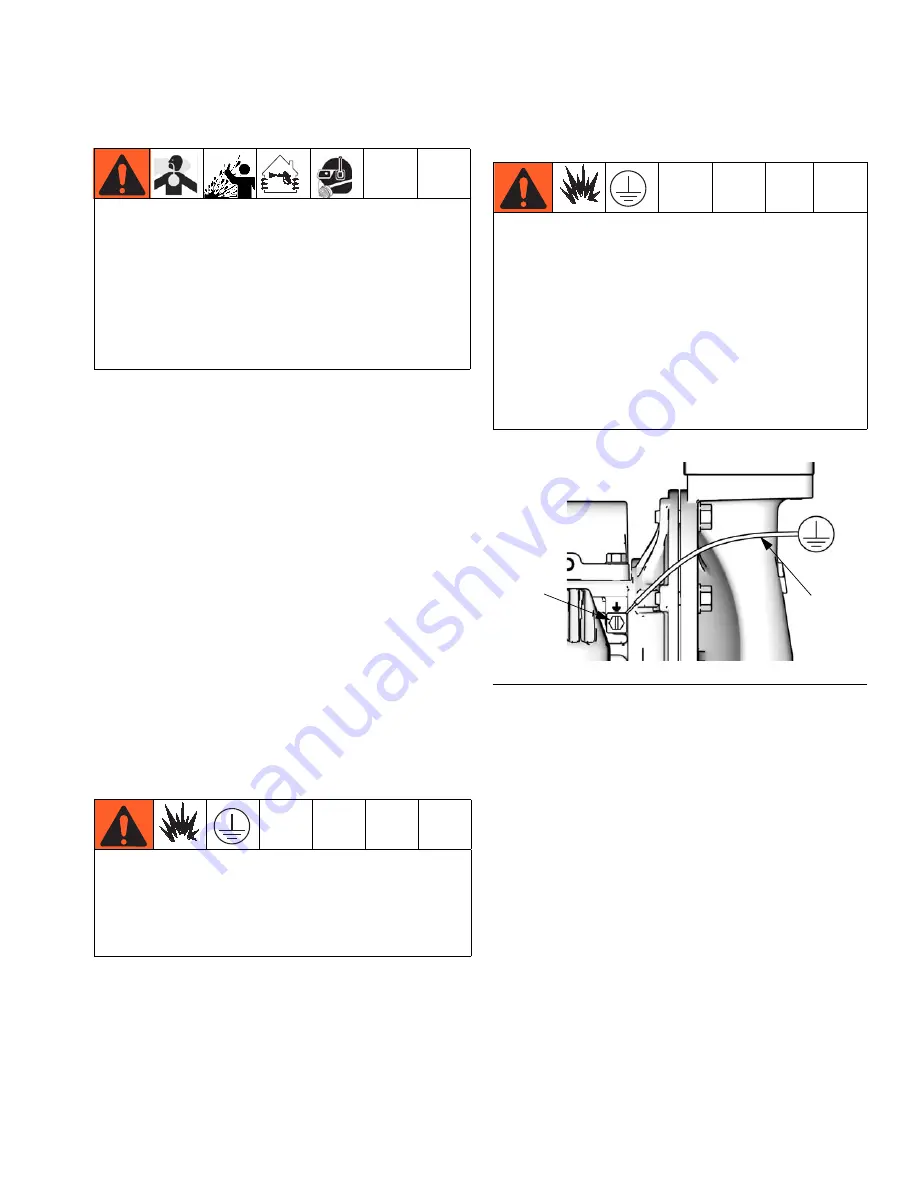

Grounding

Pump:

See F

IG

. 1. Loosen the grounding

screw (GS). Insert one end of a 12 ga.

minimum ground wire (R) behind the

grounding screw and tighten the screw

securely. Connect the clamp end of the ground

wire to a true earth ground. A ground wire and

clamp, Part 238909, is available from Graco.

Air and fluid hoses:

Use only grounded

hoses

with a maximum of 500 ft (150 m) com-

bined hose length to ensure grounding conti-

nuity.

Air compressor:

Follow manufacturer’s

recommendations.

Fluid supply container:

Follow local code.

Solvent pails used when flushing:

Follow

local code. Use only conductive metal pails,

placed on a grounded surface. Do not place

the pail on a nonconductive surface, such as

paper or cardboard, which interrupts ground-

ing continuity.

•

The pump exhaust air may contain con-

taminants. Ventilate to a remote area. See

Air Exhaust Ventilation

on page

11.

•

Never move or lift a pump under pressure.

If dropped, the fluid section may rupture.

Always follow the

Pressure Relief Proce-

dure

on page

16

before moving or lifting

the pump.

The equipment must be grounded to reduce

the risk of static sparking. Static sparking can

cause fumes to ignite or explode. Grounding

provides an escape wire for the electric

current.

Polypropylene and PVDF:

Only aluminum,

conductive polypropylene, hastelloy, and

stainless steel pumps have a ground screw.

Standard polypropylene and PVDF pumps

are

not

conductive.

Never

use a non-con-

ductive polypropylene or PVDF pump with

non-conductive flammable fluids. Follow your

local fire codes. When pumping conductive

flammable fluids,

always

ground the entire

fluid system as described.

F

IG

. 1. Grounding screw and wire

ti12214a

GS

R