Maintenance

313872B

25

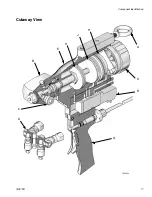

Flush Gun

1.

Follow

Pressure Relief Procedure

, page 22.

2.

Remove fluid manifold (AD).

3.

Disconnect signal cable.

4.

Install flush hoses to flush manifold 15B817. See

F

IG

. 17. Install flush manifold onto gun. Torque flush

manifold bolt to 20-30 in-lb (2.26-3.39 N•m).

5.

Holding a metal part of flush manifold firmly to side

of grounded pail and flush with compatible solvent

into a grounded metal pail. See wetted parts info in

Technical Data

, page 55. Use lowest possible fluid

pressure when flushing.

6.

Follow

Pressure Relief Procedure

, page 22.

NOTE:

For a more thorough flush, solvent flush kits are

available as an accessory. See

Accessories

on

page 53.

7.

Remove flush hoses from flush manifold. Remove

flush manifold from gun.

8.

Remove Recirculation Block 15C850 from fluid

manifold.

9.

Connect fluid manifold to gun. Torque fluid manifold

bolt to 20-30 in-lb (2.26-3.39 N•m).

10. Connect signal cable.

Clean Outside of Gun

Wipe the outside of the gun with a compatible solvent.

See materials of construction info in

Technical Data

,

page 55. Use N-Methylpyrrolidone (NMP), Dynasolve

CU-6, Dzolv, or an equivalent solvent to soften cured

material. Applying a light coat of lubricant will make

future cleaning easier.

F

IG

. 16

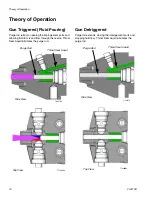

F

IG

. 17: Flush Manifold

TI14457a

AD

TI2647a

F

IG

. 18: 256510, 1 qt (0.95 liter) Solvent Cup

The solvents listed in this section may ignite if used in

flushing. Use them only for external cleaning.

TI14470a