Maintenance

10

3A4100D

Maintenance

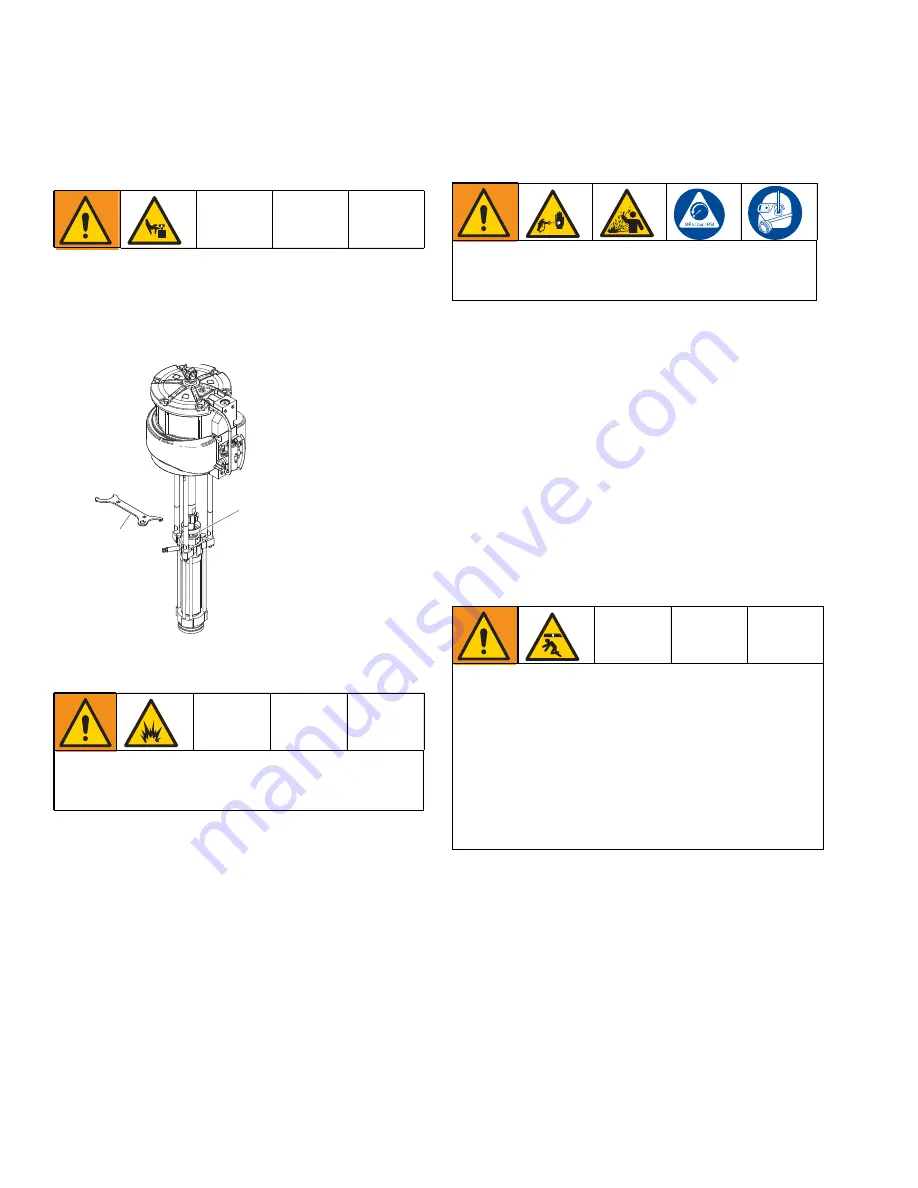

Packing Nut / Wet-Cup

1. Fill the packing nut/wet cup (P) 1/3 full with Graco

Throat Seal Liquid (TSL).

2. Use the supplied wrench (Q) to adjust the packing

nut weekly so that it is just snug. Do NOT

over-tighten.

Flushing the Pump

The pump is tested with lightweight oil, which is left in to

protect the pump parts. If the fluid you are using may be

contaminated by the oil, flush it out with a compatible

flush material before using the pump.

•

Flush at the lowest pressure possible. check

connectors for leaks and tighten as necessary.

•

Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted

parts.

1. Perform the

Pressure Relief Procedure

2. Set pump to lowest possible fluid pressure, and then

start the pump.

3. Dispense fluid into a grounded metal pail.

Disconnecting the Displacement

Pump

1. Flush the pump if you are using flushable material.

2. Stop the pump at the bottom of its stroke.

3. Perform the

Pressure Relief Procedure

4. Disconnect the air or the hydraulic hose. Plug all

hydraulic hoses immediately to prevent the contami-

nation of the hydraulic system. Hold the fluid outlet

fitting with a wrench to keep it from being loosened

while you disconnect the fluid hose.

5. Disconnect the displacement pump (G) from the

motor (F) as follows. Make sure to note the relative

position of the pump fluid outlet to the air or hydrau-

lic inlet of the motor due to orientation restrictions on

the system. If the motor does not require servicing,

leave it attached to its mounting.

6. Using adjustable wrenches to unscrew the coupling

nut (J) from the coupling adapter (H). Remove the

coupling collars (K). Take care not to lose or drop

the collars.

7. Hold the tie rod (L) flats with a wrench to keep the

rods from turning. Unscrew the hex nuts (N) from

the tie rods extensions. Carefully remove the dis-

placement pump (G) from the motor (F).

To reduce the risk of serious injury, do not flush pump

with group 1 fluids as defined by Directive 2014/68/EU

(Pressure Equipment Directive).

WLD

4

3

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the

Pres-

sure Relief Procedure

Be sure to use at least two people when lifting, moving,

or disconnecting the pump. This pump is too heavy for

one person. If you are disconnecting the displacement

pump from a motor which is still mounted (for example,

on a wall bracket), be sure to support the displacement

pump while it is being disconnected. Failure to do so

may result in the pump falling and causing injury or

property damage. Do this by securely bracing the

pump, or by having at least two people hold the pump

while another person disconnects it.