SUPER T SERIES

OM−05267

TROUBLESHOOTING

PAGE D − 3

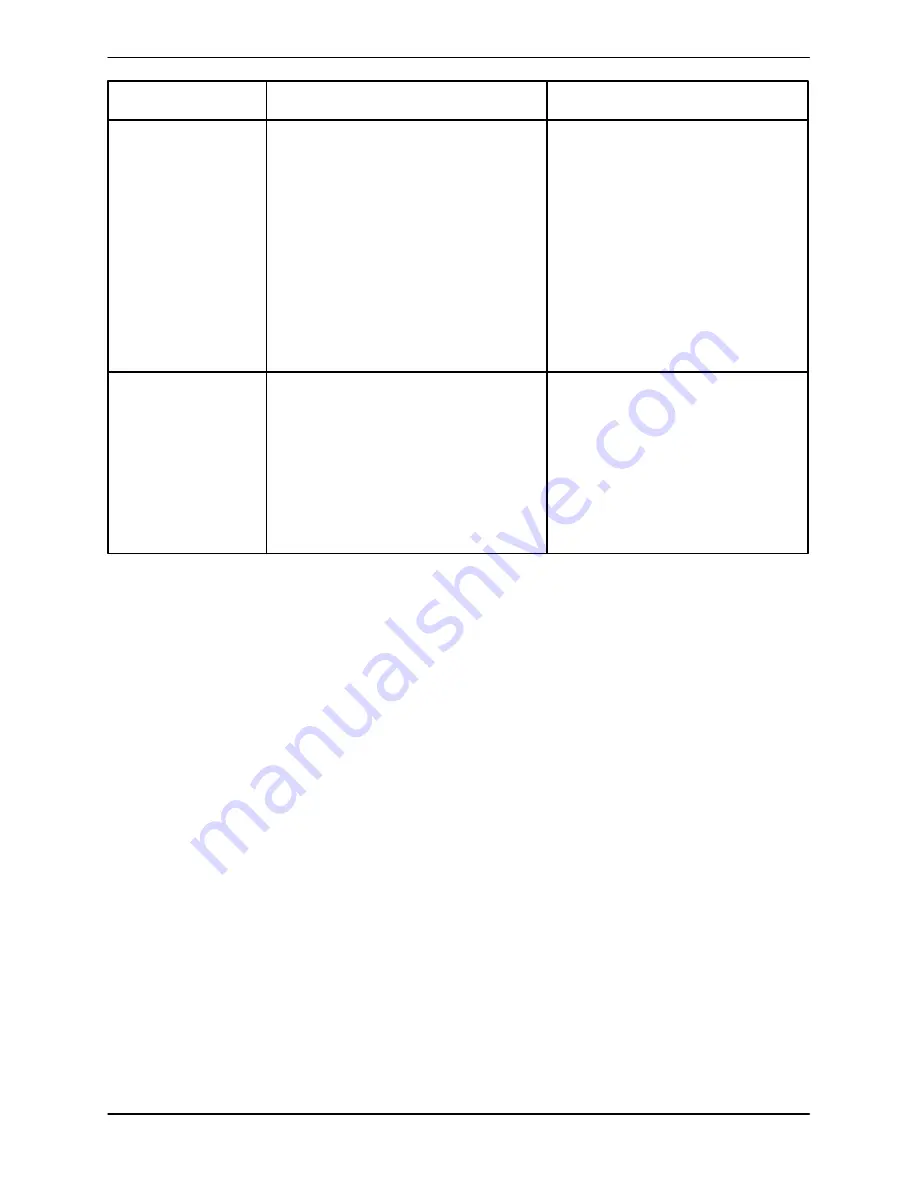

TROUBLE

POSSIBLE CAUSE

PROBABLE REMEDY

BEARINGS RUN

TOO HOT

Bearing temperature is high, but

within limits.

Check bearing temperature regu-

larly to monitor any increase.

Low or incorrect lubricant.

Check for proper type and level of

lubricant.

Suction and discharge lines not

properly supported.

Check piping installation for

proper support.

Drive misaligned.

Align drive properly.

EXCESSIVE NOISE

Cavitation in pump.

Impeller clogged or damaged.

Pump or drive not securely mounted.

Pumping entrained air.

Reduce suction lift and/or friction

losses in suction line. Record vac-

uum and pressure gauge readings

and consult local representative or

factory.

Locate and eliminate source of air

bubble.

Secure mounting hardware.

Clean out debris; replace dam-

aged parts.

PREVENTIVE MAINTENANCE

Since pump applications are seldom identical, and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

of the liquid being pumped, this section is intended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however, following a routine pre-

ventive maintenance schedule will help assure

trouble-free performance and long life from your

Gorman-Rupp pump. For specific questions con-

cerning your application, contact your Gorman-

Rupp distributor or the Gorman-Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

equipped) between regularly scheduled inspec-

tions can indicate problems that can be corrected

before system damage or catastrophic failure oc-

curs. The appearance of wearing parts should also

be documented at each inspection for comparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

before failure occurs, reducing unscheduled down

time.

For new applications, a first inspection of wearing

parts at 250 hours will give insight into the wear rate

for your particular application. Subsequent inspec-

tions should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.