25

R

Y

C

Furnace

Integrated

Control

Module

Remote Condensing Unit

(Single-Stage Cooling)

R

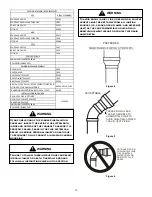

Thermostat - Single -Stage Heating with Single-Stage

Cooling

NOTE:

To apply a single-stage Heating Thermostat, the thermostat

selector switch on the Integrated Control Module

must

be set on

single-stage.

Figure 34

R

Y

C

Furnace

Integrated

Control

Module

Remote Condensing Unit

(Single-Stage Cooling)

R

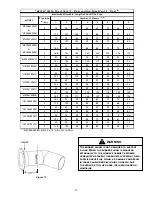

Thermostat - Two-Stage Heating with Single-Stage Cooling

Figure 35

W1 W2

Y

Furnace

Integrated

Control

Module

Remote Condensing Unit

(Two-Stage Cooling)

Y2

W1 W2

Y2

Thermostat - Two-Stage Heating with Two-Stage Cooling

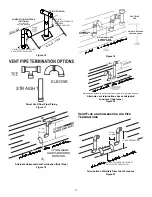

Thermostat Wiring Diagrams

Figure 36

Single-Stage Heating Thermostat

Application

A single-stage thermostat with only one heating stage may be

used to control this furnace. The application of a single-stage

thermostat offers a

timed

transition from low to high fire. The

furnace will run on low stage for a fixed period of time before

stepping up to high stage to satisfy the thermostat’s call for

heat. The delay period prior to stepping up can be set at

either a fixed 10 or 20 minute time delay or a load based

variable time between 1 and 12 minutes (AUTO mode). If

the AUTO mode is selected, the control averages the cycle

times of the previous three cycles and uses the average to

determine the time to transition from low stage to high stage.

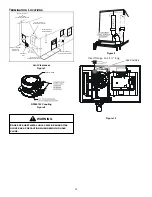

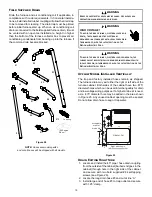

PCBBF139 CONTROL BOARD

1

2

3

4

2 STAGE STAT

OFF OFF

1 STG STAT 10 min delay

ON OFF

1 STG STAT 20 min delay

ON

ON

AUTO

OFF* ON*

90

OFF OFF

120

OFF ON

150

ON* OFF*

180

ON

ON

* Factory Setting

DIP SWITCH

SWITCH

GROUP

FUNCTION

S3

S3

Heating

Fan Off

Delay

PURPOSE

Thermostat

Setup

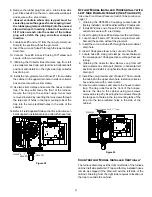

Fossil Fuel Applications

This furnace can be used in conjunction with a heat pump

in a fossil fuel application. A fossil fuel application refers to

a combined gas furnace and heat pump installation which

uses an outdoor temperature sensor to determine the most

cost efficient means of heating (heat pump or gas furnace).

A heat pump thermostat with

three stages of heat

is required

to properly use a two-stage furnace in conjunction with a heat

pump. Refer to the fossil fuel kit installation instructions for

additional thermostat requirements.

Strictly follow the wiring guidelines in the fossil fuel kit instal

-

lation instructions. All furnace connections must be made

to the furnace two-stage integrated control module and the

“FURNACE” terminal strip on the fossil fuel control board.

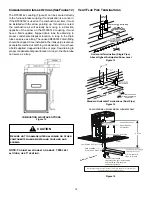

Twinning

Using the “TWIN” terminals and proper wiring enables two

*MEC96 furnaces of the same model and size to be twinned.

Twinning allows simultaneous operation of two furnaces and

forces the indoor blower motors of each furnace to operate

synchronously into a common duct system. Using the twin

-

ning function will require only field installed wiring with no

external kits or parts.

·

The staging DIP switches and speed tap DIP

switches must be set the same on both furnaces.

NOTE: Each furnace must be connected to it’s own

115 VAC power supply. The L1 connection to each

furnace must be in phase (connected to circuit

breakers on the same 115 VAC service panel phase

leg). To verify that the furnaces are in phase, check

from L1 to L1 on each furnace with a voltmeter. If

the furnaces are in phase, the voltage between both

furnaces will be

ZERO.