P

roduct

s

PeciFications

P

roduct

s

PeciFications

SS-GMVM96

www.goodmanmfg.com

5

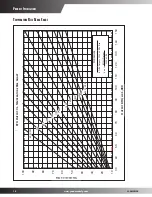

gcVM96 d

iMensions

FOLDED FLANGES

UNFOLDED FLANGES

FOLDED FLANGES

UNFOLDED FLANGES

M

iniMuM

c

learances

to

c

oMbustible

M

aterials

Position

Sides

Rear

Front

Bottom

Flue

Top

Downflow

0”

0”

3”

NC

0”

1”

Horizontal

6”

0”

3”

C

0”

6”

C = If placed on combustible floor, the floor MUST be wood ONLY.

NC = For installation on non-combustible floors only. A combustible floor sub-base must be used for installations on combustible flooring.

Notes

• For servicing or cleaning, a 24” front clearance is required.

• Unit connections (electrical, flue and drain) may necessitate greater clearances than the minimum clearances listed above.

• In all cases, accessibility clearance must take precedence over clearances from the enclosure where accessibility clearances are greater.

Model

W

D

H

A

B

C

D

E

GCVM960604CX

21"

28¾"

40¾"

21"

19½”

16⅛"

18"

19½”

GCVM960805DX

24½”

28¾"

40¾"

24½”

23"

20⅝"

21½”

23"

GCVM961005DX

24½”

28¾"

40¾"

24½”

23"

20⅝"

21½”

23"

Notes:

• Installer must supply one or two PVC pipes: one for combustion air (optional) and one for the flue outlet (required). Vent pipe must be either 2” or

3” in diameter, depending upon furnace input, number of elbows, length of run, and installation (1 or 2 pipes). The optional Combustion Air Pipe is

dependent on installation/code requirements and must be 2” or 3” diameter PVC.

• Line voltage wiring can enter through the right or left side of the furnace. Low-voltage wiring can enter through the right or left side of furnace.

• Conversion kits for high-altitude natural gas operation are available. Contact your Goodman distributor or dealer for details.

• Installer must supply following gas line fittings, according to which entrance is used:

Left—Two 90º elbows, one close nipple, straight pipe

Right—Straight pipe to reach gas valve

• For bottom return: Failure to unfold flanges may reduce airflow by up to 18%. This could result in performance and noise issues.